In modern food and beverage manufacturing, getting it right means more than taste and packaging – it’s about consistency, safety and visual perfection. Machine vision cameras, when properly implemented, help ensure we catch defects, meet hygiene standards and keep up with consumer expectations. Below are ways high-quality imaging systems upgrade quality control.

1. Color Accuracy for Sorting & Grading

Many food items are sorted based on color and appearance (think fruit ripeness, color uniformity or detecting bruises). Vision systems with excellent color fidelity allow automatic grading with precision.

- Prism-based cameras capture high-fidelity color, helping vision systems reliably differentiate ripe vs. unripe fruit or detect subtle discolorations.

- Accurate color helps in packaging / label inspection, ensuring products look appealing and consistent.

2. Speed Without Sacrificing Quality

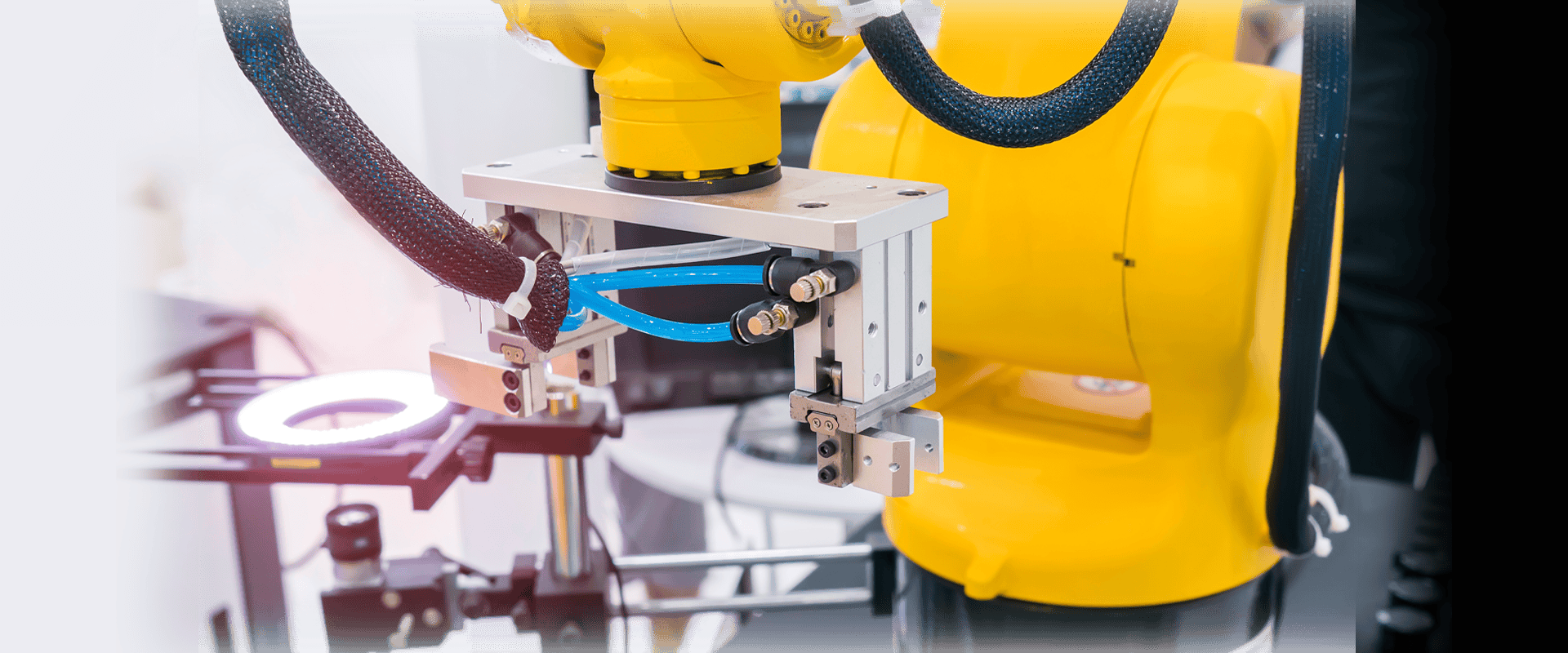

Food production lines are fast. Cameras must keep up with high throughput without missing defects.

- Line-scan and area-scan cameras provide high frame rates to manage rapid inspection of items conveyed in bulk (nuts, grains, vegetables) or moving quickly.

- In beverages, high speed allows inspection of fill levels, label placement, cap alignment at high speed, reducing bottlenecks in bottling lines.

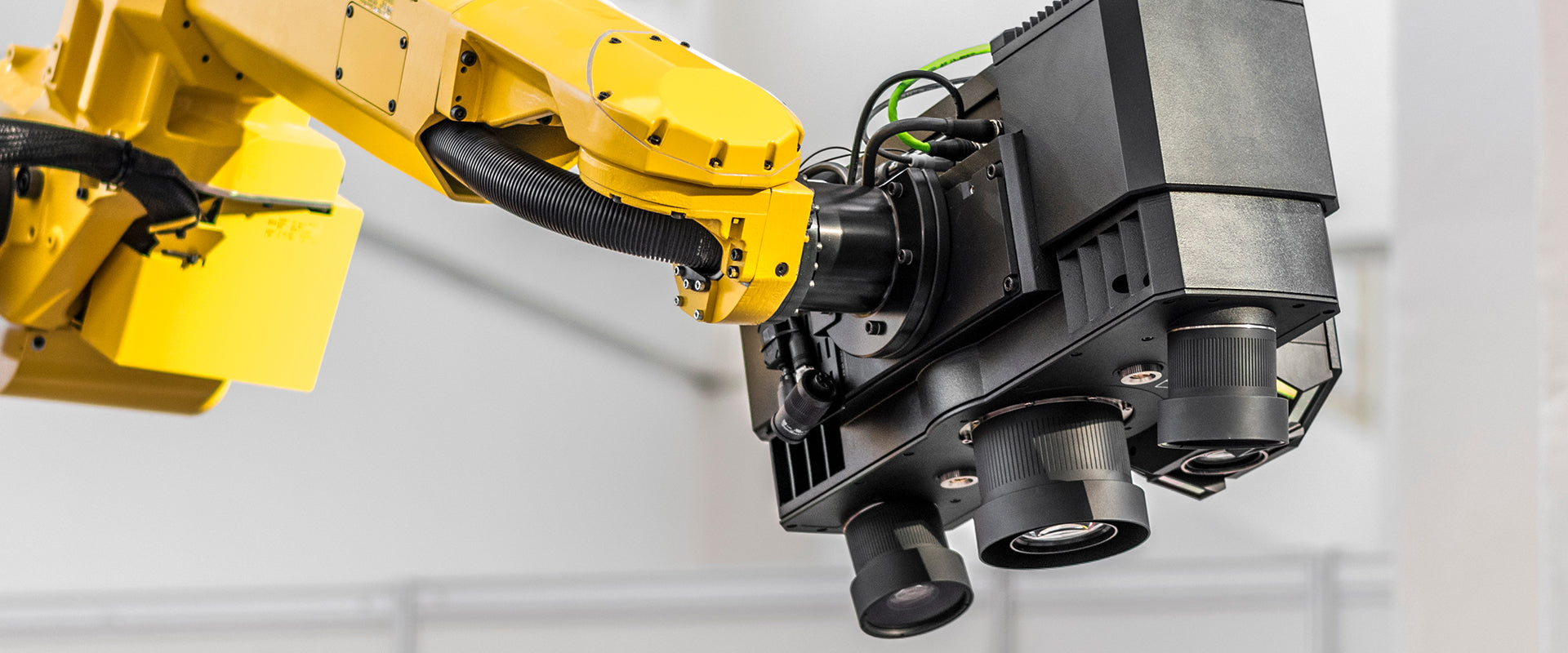

3. Multispectral & Near-Infrared (NIR) Imaging

Some defects are invisible in visible light – like moisture content, early decay, foreign material or internal flaws. Multispectral or VIS (visible) + NIR/SWIR (short-wave infrared) cameras expand what we can see.

- Dual-wavelength cameras help identify bruises under fruit skin or detect early signs of spoilage.

- NIR imaging is also used to detect foreign objects or contaminants that are not obvious in VIS.

4. Inspection of Fill Levels, Labeling & Packaging

Beyond the raw product, appearance matters in packaging: does the bottle look correct, is the cap aligned, is the label in place and readable, are seals clean? Poor packaging can lead to recalls or customer dissatisfaction.

- High-resolution, robust cameras help detect mislabels, missing or damaged caps, misaligned bottles and cleanliness issues (dirty bottles, residues).

- Proper physical construction and durability are essential since many imaging stations operate in wet, dusty or otherwise harsh food / packaging environments.

5. Consistency, Traceability & Reduced Waste

Machine vision helps drive consistency, ensuring products leaving the line meet defined standards. This reduces waste from rejected batches, decreases recalls and preserves brand reputation. It also helps with traceability when parts are tagged or labeled properly.

- Continuous monitoring via cameras ensures that deviation from quality standards is caught early, and process adjustments can be made in real time.

- Less waste, better safety records and higher consumer trust also come from maintaining strict visual inspection using dependable imaging equipment.

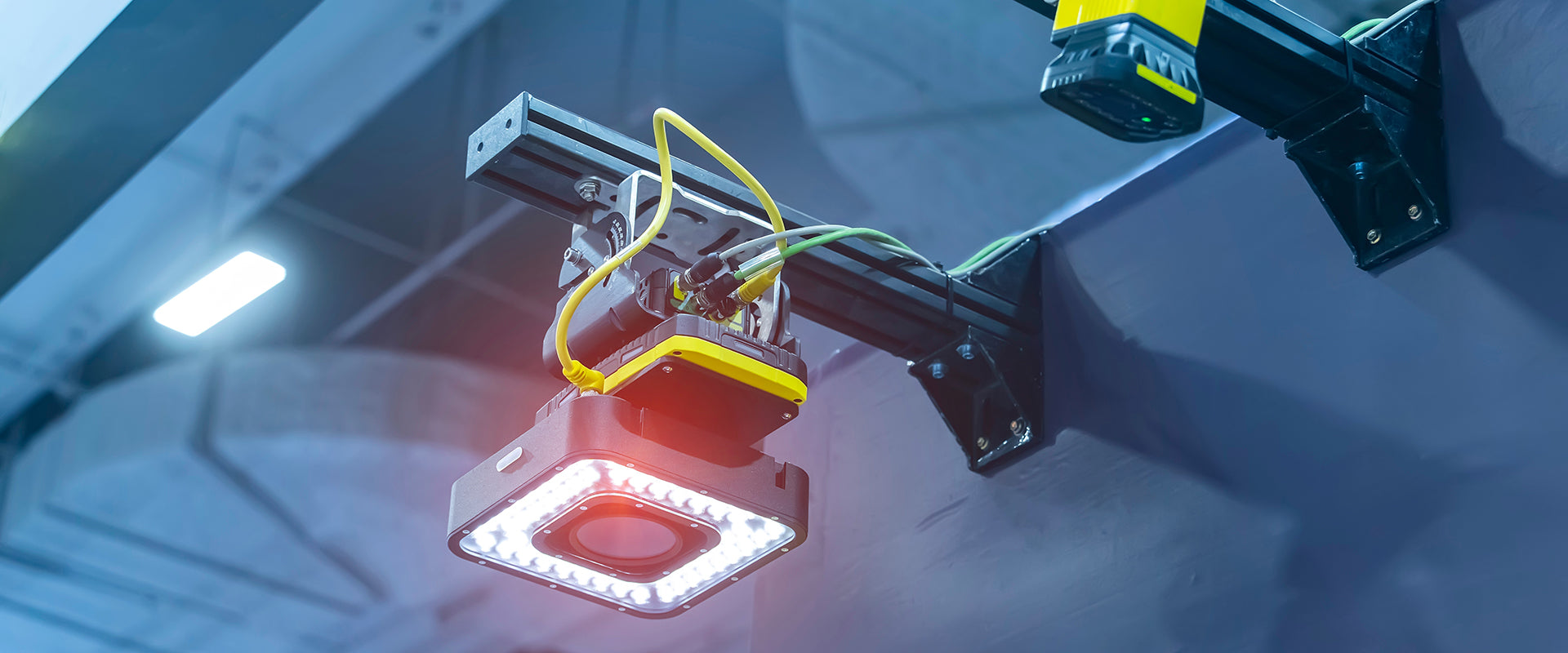

Lighting

Lighting