Selecting the right industrial inspection camera is one of the most critical decisions in machine vision system design. The wrong choice can result in missed defects, false rejects, reduced production speed, and costly downtime.

Designing a high-performance machine vision system requires more than selecting a camera and turning on a light. In industrial inspection environments, image quality determines measurement accuracy, defect detection reliability, and production efficiency.

Machine vision cameras are the backbone of any inspection, measurement or automation system. But as sensor technology, interfaces and processing demands evolve, older cameras can quietly become a bottleneck, limiting performance, accuracy and scalability. If your system is struggling to keep up, it may be time for an upgrade.

Quality standards continue to rise in manufacturing environments while defect tolerance grows increasingly narrow. Traditional machine vision systems, typically relying on standard color or monochrome sensors, can struggle to catch flaws that are invisible to the human eye or obscured by lighting, surface finishes or material properties. Because of this, multispectral imaging has become a powerful tool for advanced inspection.

In today’s connected cities, intelligent traffic systems (ITS) and automatic number plate recognition (ANPR) are essential tools for improving safety, enforcing regulations and streamlining traffic flow. At the heart of these systems are machine vision cameras –designed to capture clear, precise images in complex, fast-changing environments.

In modern food and beverage manufacturing, getting it right means more than taste and packaging – it’s about consistency, safety and visual perfection. Machine vision cameras, when properly implemented, help ensure we catch defects, meet hygiene standards and keep up with consumer expectations. Below are ways high-quality imaging systems upgrade quality control.

The choice of camera interface plays a crucial role in machine vision system performance. The most common three interfaces are GigE, USB3 Vision and CoaXPress.

In industrial imaging, choosing the right camera for a machine vision system can significantly impact performance and accuracy. One of the most fundamental decisions is whether to use a monochrome or color camera.

When it comes to precision inspection and high-speed applications, line scan cameras are a cornerstone of modern industrial imaging.

As technology advances, line scan cameras are increasingly being adopted across a broader range of mainstream applications, driven by innovations in sensor technology, interface options, and the demand for more compact and efficient systems.

Lighting

Lighting

This 2026 optimization guide explains how lighting and filters work together, when to use each, and how to design the right combination for industrial inspection applications.

In machine vision, lighting isn’t just about brightness – it’s about control. One of the biggest challenges in capturing consistent, high-quality images is glare and reflections from shiny or specular surfaces. These unwanted highlights can obscure critical details, confuse algorithms and lower inspection accuracy. This is where polarized lighting plays a powerful role, offering a practical solution to suppress glare and reveal hidden detail in reflective environments.

When it comes to machine vision, one of the most influential lighting variables is lighting angle, which directly impacts contrast, edge definition, surface visibility and defect detection. Selecting the correct lighting angle can mean the difference between a reliable inspection system and inconsistent results.

Lighting is one of the most influential factors in machine vision performance. The right illumination can dramatically improve contrast, reduce noise and stabilize inspection results, while the wrong setup can cause missed defects, blurry images or inconsistent measurements.

There are many lighting techniques in machine vision, but backlighting – placing an illumination source behind the object, opposite the camera – is especially effective for certain applications. While front-lighting or diffuse dome lighting might illuminate a surface, backlighting creates a clean silhouette by allowing light to pass through or around the subject. This technique is particularly useful for edge detection, shape verification and measurement tasks.

Machine vision has come a long way, and LED lighting has been a key driver. As inspection speeds increase, product surfaces become more challenging and lighting conditions more difficult, high-quality LED lighting solutions have evolved to meet these demands. Below is a look at how LED lighting for vision applications has developed, and what modern systems demand.

Lighting determines how surfaces, textures and edges appear to the imaging system – and ultimately how well the application performs. Three of the most common lighting approaches are diffuse, direct and structured.

In machine vision, lighting is important. The quality, angle and consistency of illumination directly impact the ability of your vision system to capture accurate, reliable images. Among the many lighting considerations, one crucial yet often overlooked factor is uniformity – achieving even, consistent illumination across the entire field of view.

When it comes to building a successful machine vision system, lighting is just as critical as the camera or lens. Without the right lighting, even the most advanced imaging components can produce inconsistent or unreadable results. Whether you're inspecting tiny electronics, scanning barcodes on packaging lines or ensuring quality control in manufacturing, the right lighting solution makes all the difference.

In machine vision, lighting isn’t just about brightness – it’s about control. One of the biggest challenges in capturing consistent, high-quality images is glare and reflections from shiny or specular surfaces. These unwanted highlights can obscure critical details, confuse algorithms and lower inspection accuracy. This is where polarized lighting plays a powerful role, offering a practical solution to suppress glare and reveal hidden detail in reflective environments.

Selecting the right lens is critical to the success of any machine vision system. While cameras and lighting often get the spotlight, the lens ultimately determines image clarity, field of view, magnification and inspection accuracy. Two of the most common lens types used in industrial imaging are fixed focal lenses and zoom lenses, each with distinct advantages depending on the application.

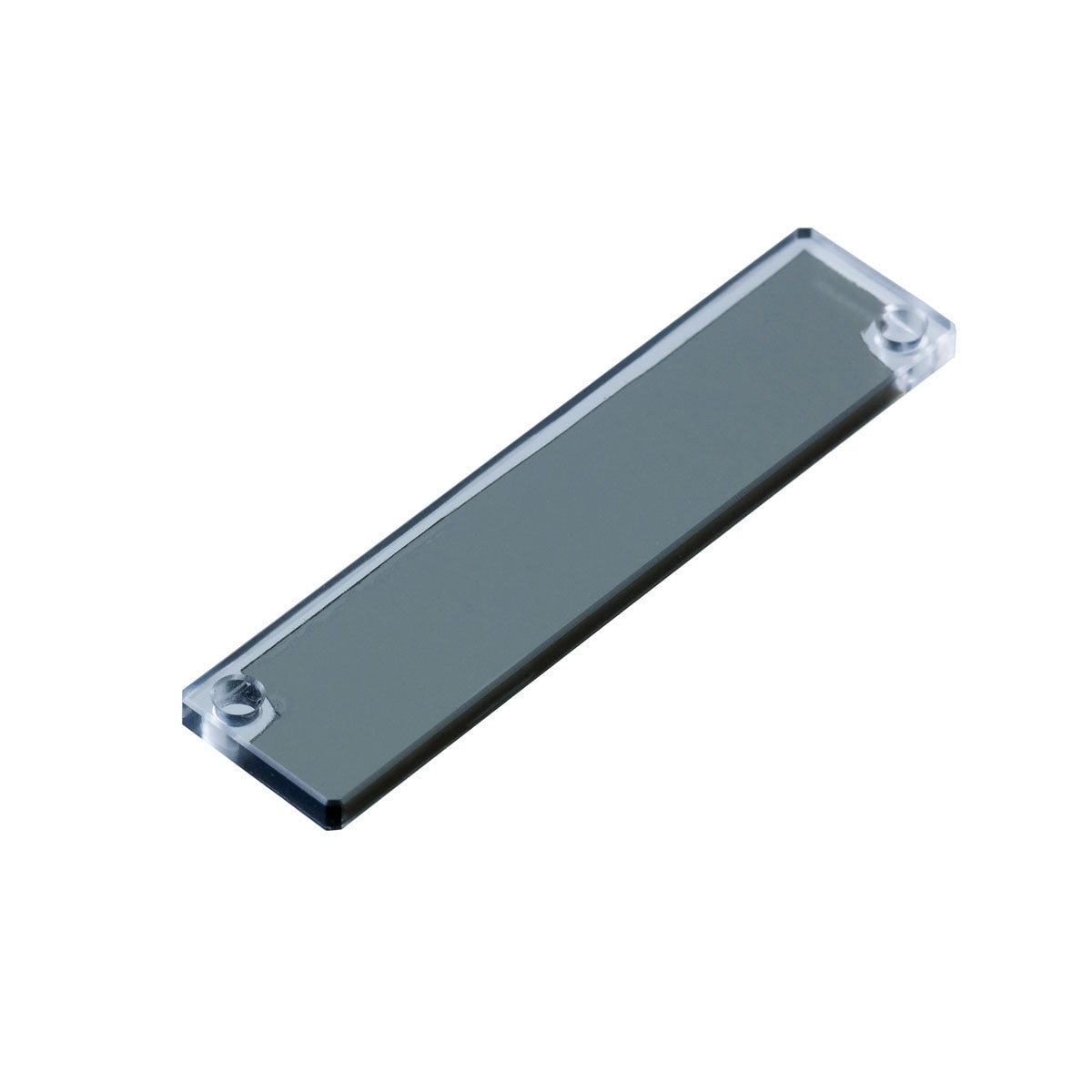

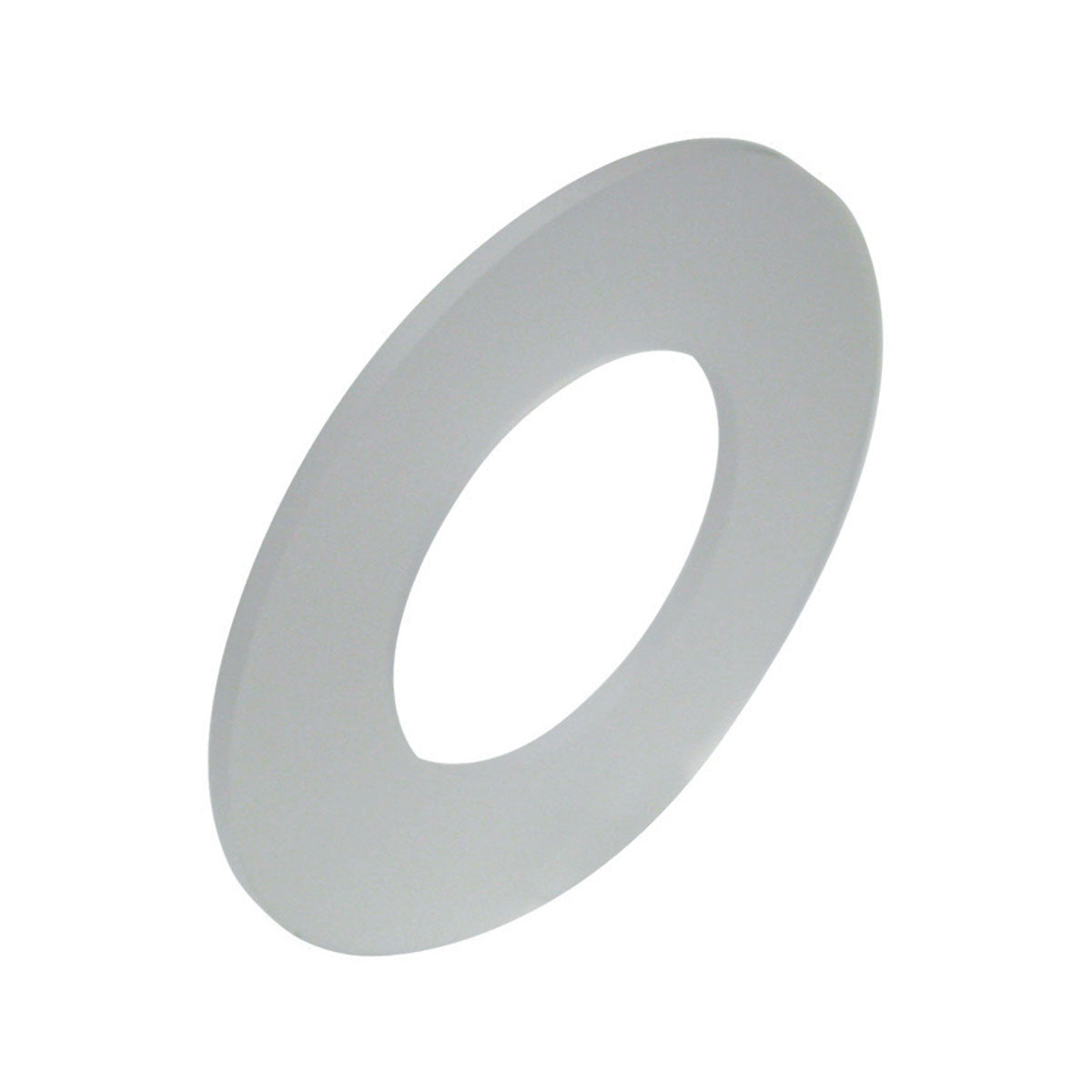

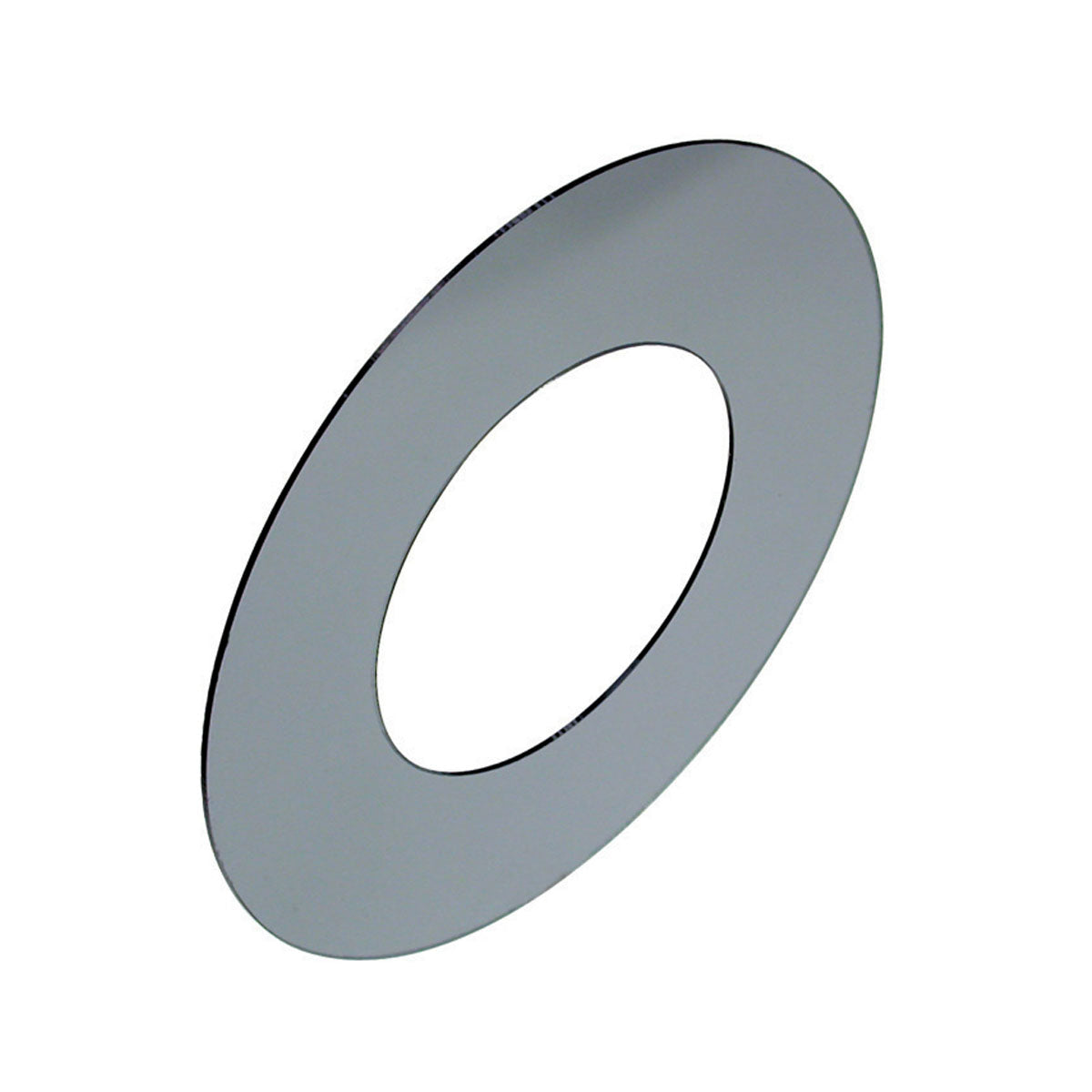

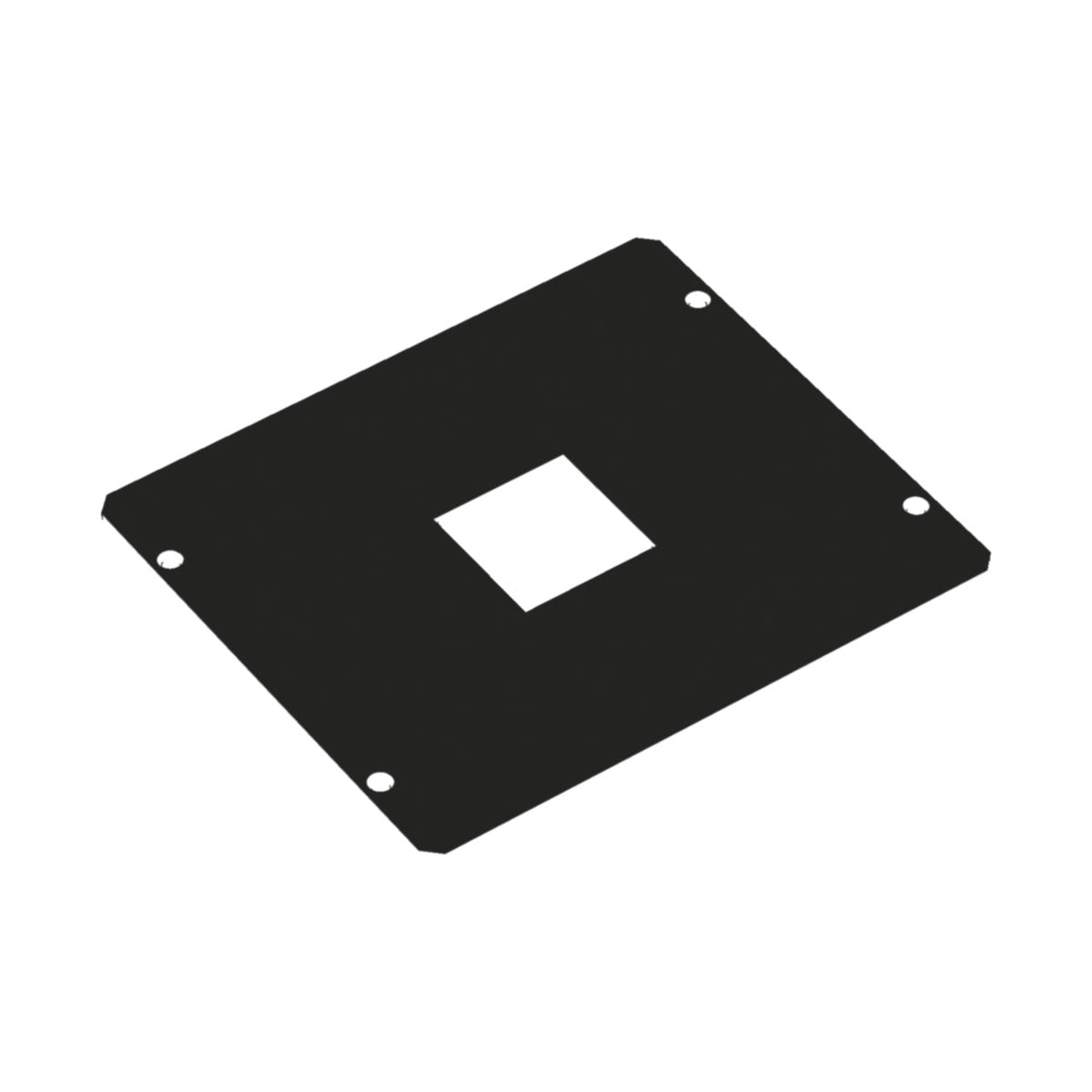

In machine vision systems, optical filters play a critical role in controlling light, improving contrast and enhancing image accuracy. But even the best filter can't perform as intended if it's not mounted correctly. Mounting solutions for machine vision filters are a foundational yet often overlooked part of system design, directly affecting alignment, stability, repeatability and overall image quality.

In machine vision applications, accuracy is everything. Even small optical errors can lead to failed inspections, incorrect measurements or reduced system reliability. One of the most common optical challenges is lens distortion. Understanding what lens distortion is and how to minimize it is critical when designing precision vision systems for inspection, measurement and automation.

CCS America is a trusted provider of industrial machine vision lighting systems designed to deliver uniform, high-intensity illumination for demanding imaging applications. Across automation, quality inspection, measurement, and robotics, CCS lighting solutions help machine vision cameras capture clear, consistent images even in challenging industrial environments.

At FJW Optical, we provide a full portfolio of CCS lighting products that support a wide range of machine vision systems. From ring lights and bar lights to dome and backlighting solutions, CCS machine vision lights are engineered to optimize contrast, reduce shadows, and enhance image fidelity — all critical factors in precision inspection and automated imaging workflows.

Machine vision systems rely on consistent, controlled lighting to capture accurate visual data. Unlike general illumination, machine vision lighting is specifically tuned to highlight object features, improve contrast, and stabilize image quality regardless of ambient conditions.

Poor lighting can lead to:

CCS lighting systems are designed to eliminate these issues by providing stable, customizable illumination for any vision application.

CCS ring lights surround the camera lens to provide even, shadow-free illumination. They are ideal for:

Bar lights deliver linear illumination optimized for elongated fields of view and conveyance systems. These are commonly used for:

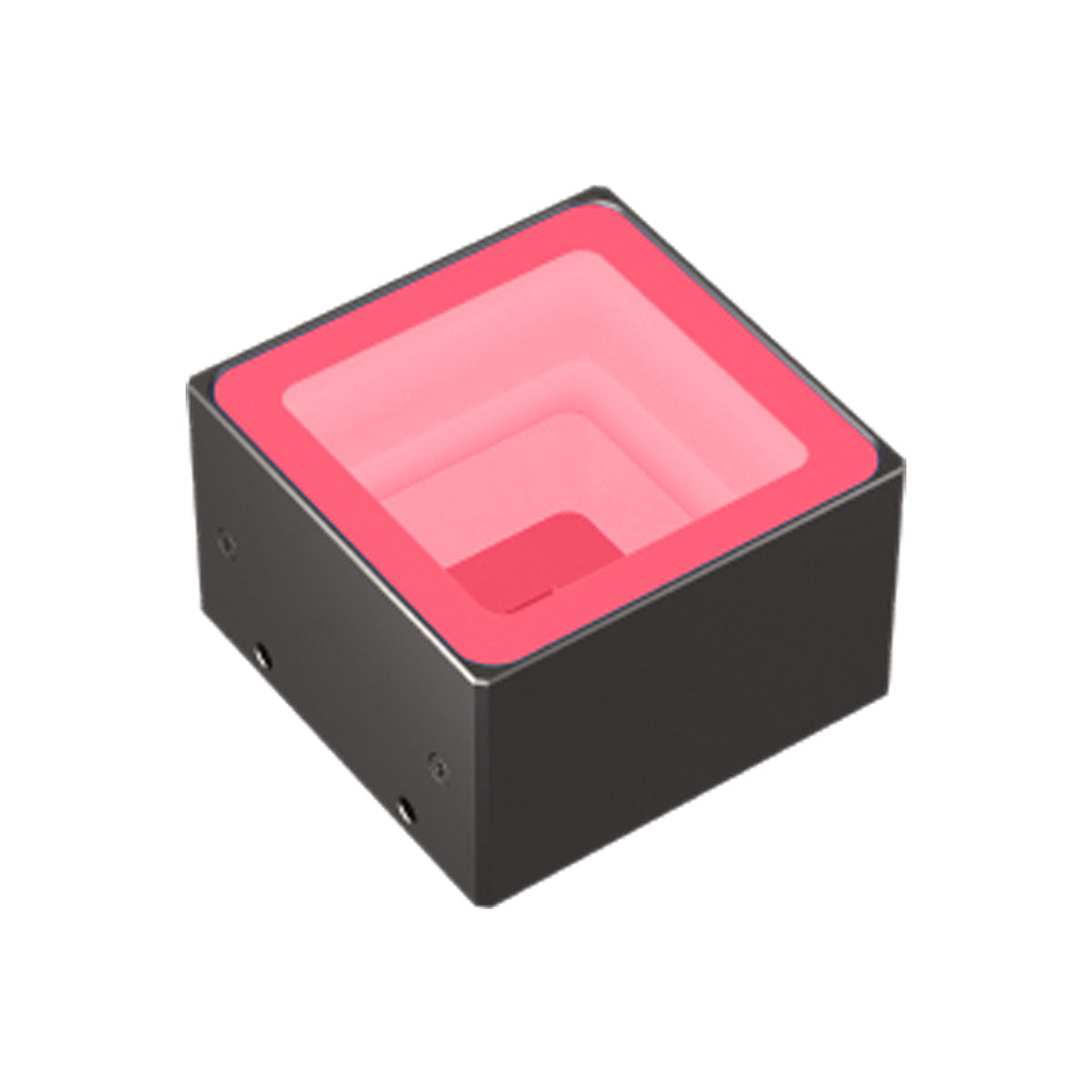

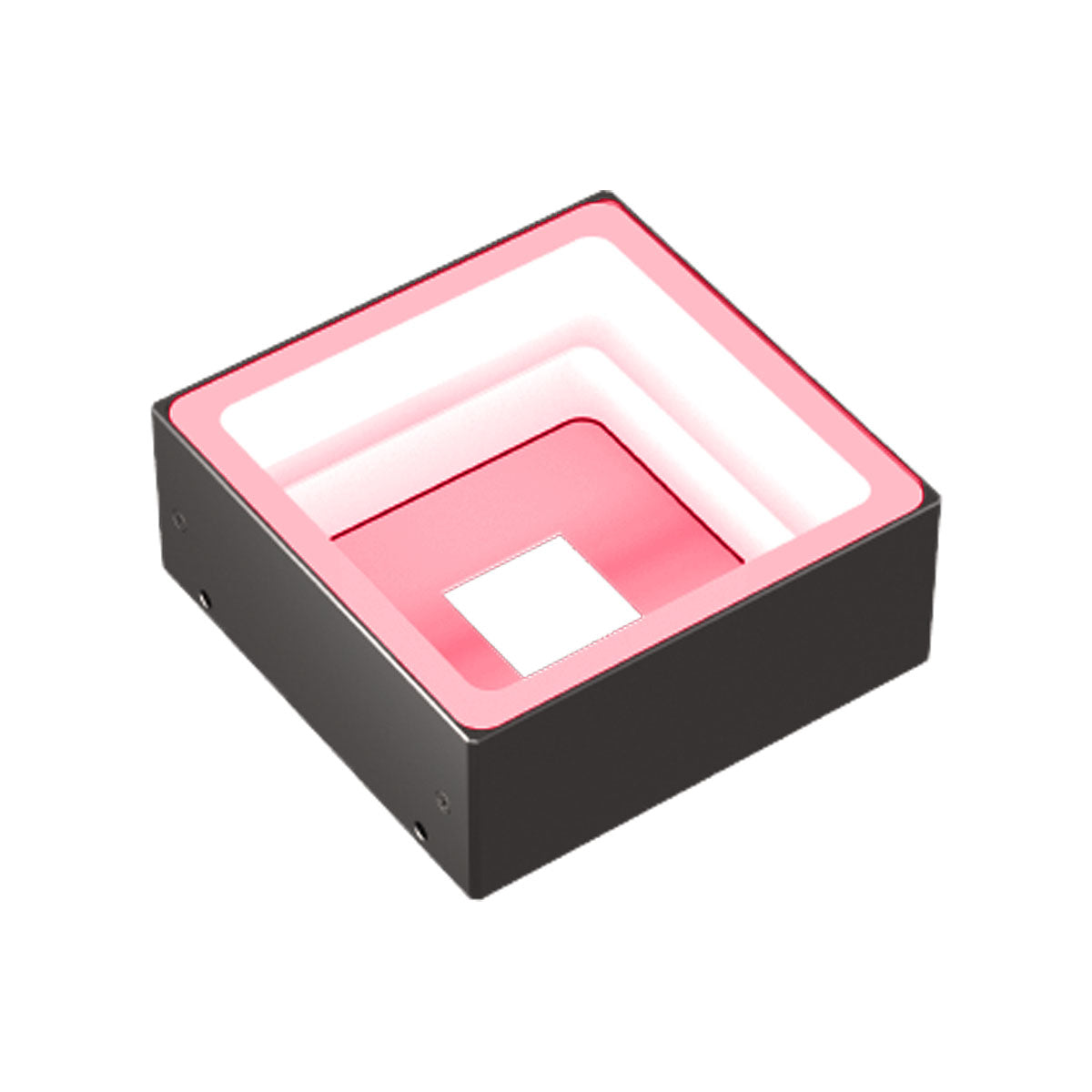

Dome lights provide diffuse, shadow-free illumination that works exceptionally well for:

Backlights provide silhouette imaging by placing the light source behind the object. This helps emphasize:

Each lighting type serves a specific imaging purpose and can be selected based on inspection goals and environmental conditions.

CCS lighting systems are engineered to provide consistent brightness across the field of view, eliminating hot spots and uneven lighting.

Many CCS lights support adjustable intensity, allowing precise tuning for specific camera exposure settings.

Built for industrial environments, CCS machine vision lights are rugged and capable of operating continuously under:

CCS lights are compatible with major machine vision camera brands and can be synchronized with camera triggers for optimized image capture.

CCS lighting solutions are used across a variety of industries where automated imaging plays a critical role:

These lighting systems help ensure consistent vision performance across production lines and high-speed inspection tasks.

Selecting the appropriate lighting depends on several factors:

Understanding these elements will help you choose the most effective CCS lighting solution for your machine vision system.

Proper lighting improves contrast and clarity, making it easier for vision software to detect features and defects.

Stable, repeatable lighting minimizes false positives and false negatives, increasing overall system reliability.

Optimized lighting reduces the need for multiple imaging passes, enabling faster inspection cycles.

Industrial lighting built for durability minimizes failures and maintenance interruptions.

These benefits translate into more efficient automation processes and higher confidence in automated decision-making.

When you choose CCS machine vision lights from FJW Optical, you gain:

Our team works with engineers and vision integrators to ensure you choose the right lighting combination to maximize performance and streamline your automation workflow.

CCS machine vision lights are designed specifically to deliver uniform, high-contrast illumination optimized for camera sensors and imaging applications, unlike general industrial lighting.

CCS offers ring lights, bar lights, dome lights, and backlights tailored to different machine vision inspection tasks.

Consider object surface type, field of view, camera specifications, and inspection goals when selecting a lighting solution.

Yes, many CCS lights support external triggering and synchronization with camera exposure settings.

Absolutely — CCS lighting systems are engineered to support high frame rates and rapid imaging needs.

Yes — they are built for rugged industrial use, including vibration, dust exposure, and continuous operation.

Common industries include automotive, electronics, manufacturing, food & beverage, and logistics.

Yes — by enhancing contrast and edge definition, CCS lights help vision systems detect defects more reliably.