Industrial Optical Filters for Machine Vision & Industrial Imaging

Optical filters play a critical role in machine vision and industrial imaging systems, helping improve image clarity, contrast, and accuracy in demanding environments. Industrial optical filters are designed to precisely control the wavelengths of light reaching a camera sensor, enabling reliable image capture for inspection, measurement, automation, and quality control applications.

At FJW Optical, we offer a comprehensive selection of industrial optical filters for machine vision, automation, robotics, scientific imaging, and inspection systems. Our filters are engineered to meet the performance, durability, and consistency requirements of modern industrial applications.

Whether you need to eliminate unwanted light, enhance contrast, reduce glare, or isolate specific wavelengths, our optical filters provide dependable performance for professional imaging systems.

What Are Industrial Optical Filters?

Industrial optical filters are precision components placed in front of cameras, lenses, or sensors to selectively transmit, absorb, or block specific wavelengths of light. In machine vision systems, filters help ensure that cameras capture clean, accurate, and repeatable images, even in challenging lighting conditions.

Optical filters enhance image contrast when used alongside industrial cameras, specialized lenses, and optimized lighting systems.

Unlike consumer-grade camera filters, industrial optical filters are designed for:

- Continuous operation

- High-temperature and high-vibration environments

- Compatibility with machine vision cameras and lenses

- Consistent optical performance over long periods

They are essential for improving system reliability and inspection accuracy in automated environments.

Why Optical Filters Are Essential in Machine Vision Systems

Machine vision systems rely on consistent lighting and image quality to make accurate decisions. Optical filters help optimize imaging performance by controlling how light interacts with the camera sensor.

Key Benefits of Using Industrial Optical Filters

Improved Image Contrast and Clarity

Filters reduce background noise and unwanted reflections, allowing vision systems to clearly detect edges, defects, or features.

Reduced Glare and Reflections

Polarizing and specialty filters minimize glare from reflective surfaces such as metal, glass, and plastic.

Enhanced Color and Wavelength Accuracy

Bandpass and color filters isolate specific wavelengths, improving accuracy in color inspection and spectral analysis.

Better Performance in Variable Lighting

Filters stabilize image quality in environments with inconsistent or harsh lighting conditions.

Increased Inspection Accuracy

Cleaner images result in fewer false positives and more reliable automated inspections.

Types of Optical Filters Available for Industrial Imaging

FJW Optical offers a wide range of machine vision filters designed for different applications and imaging requirements.

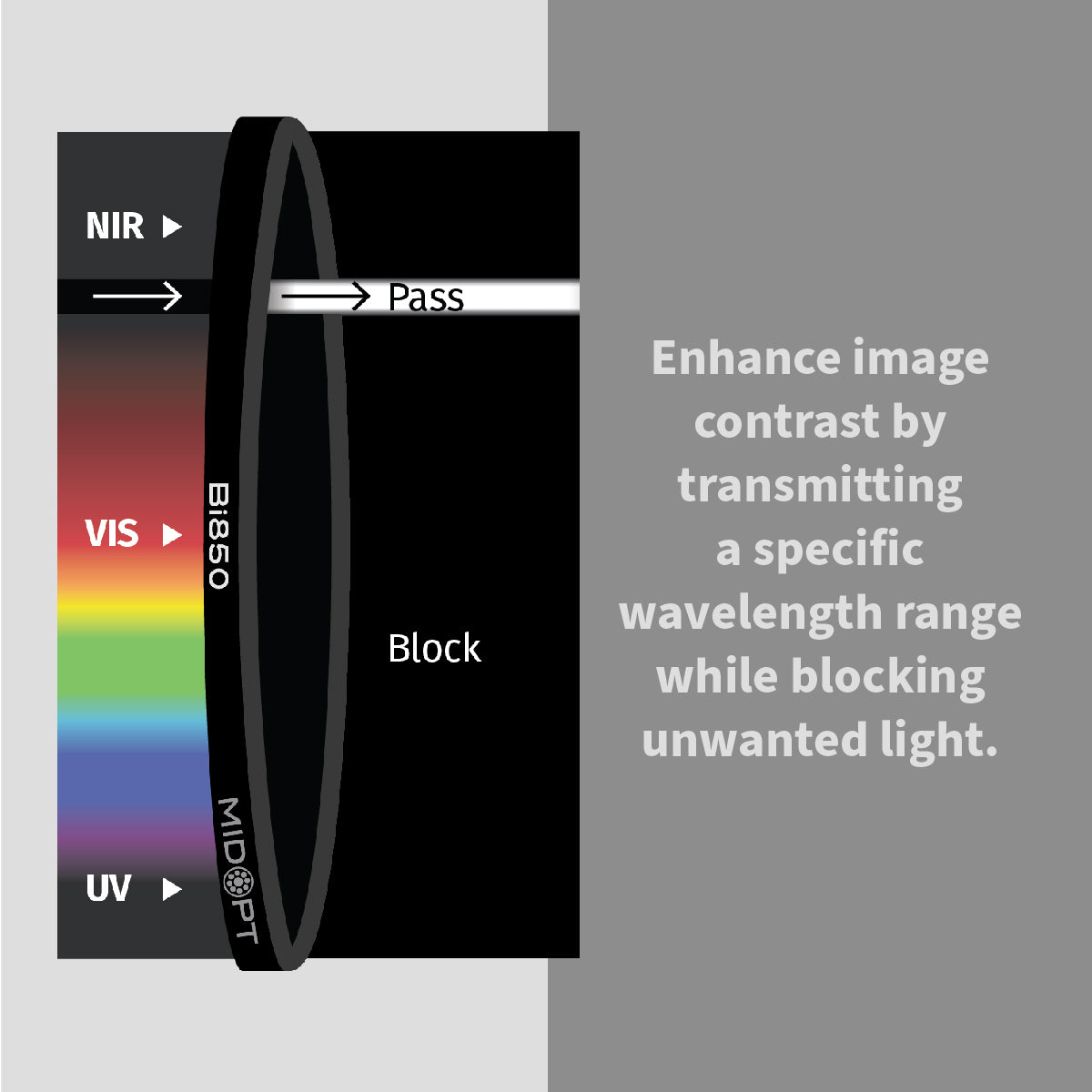

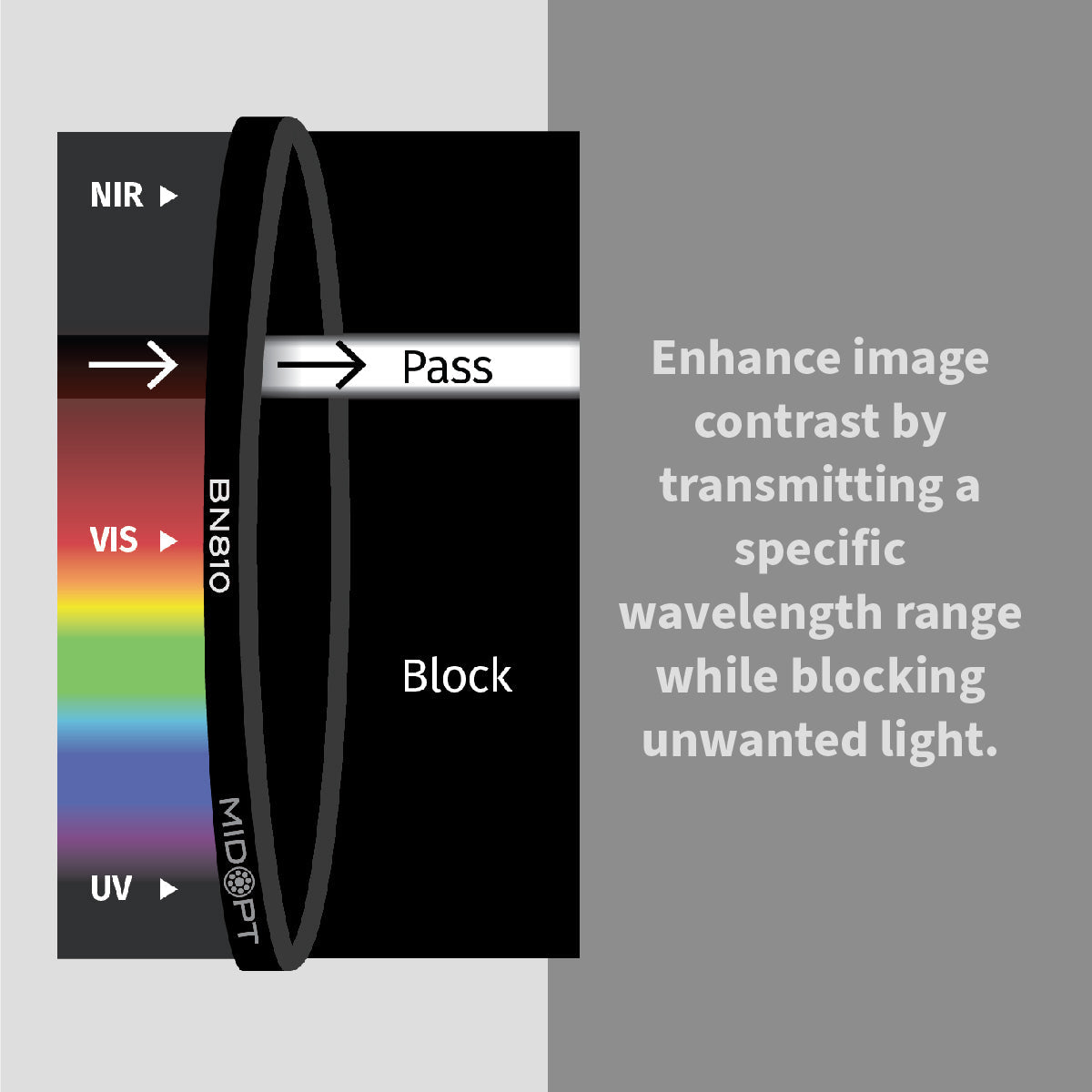

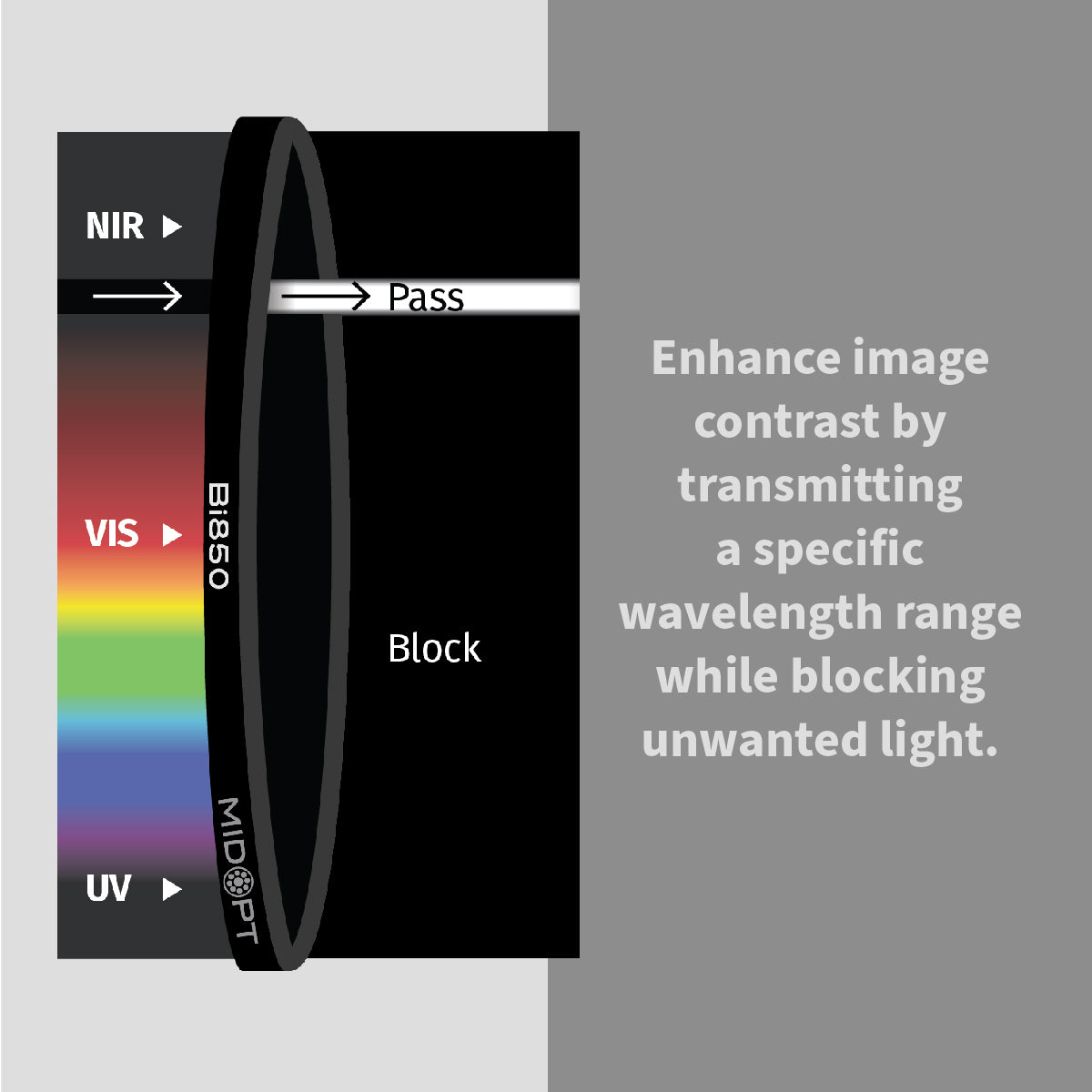

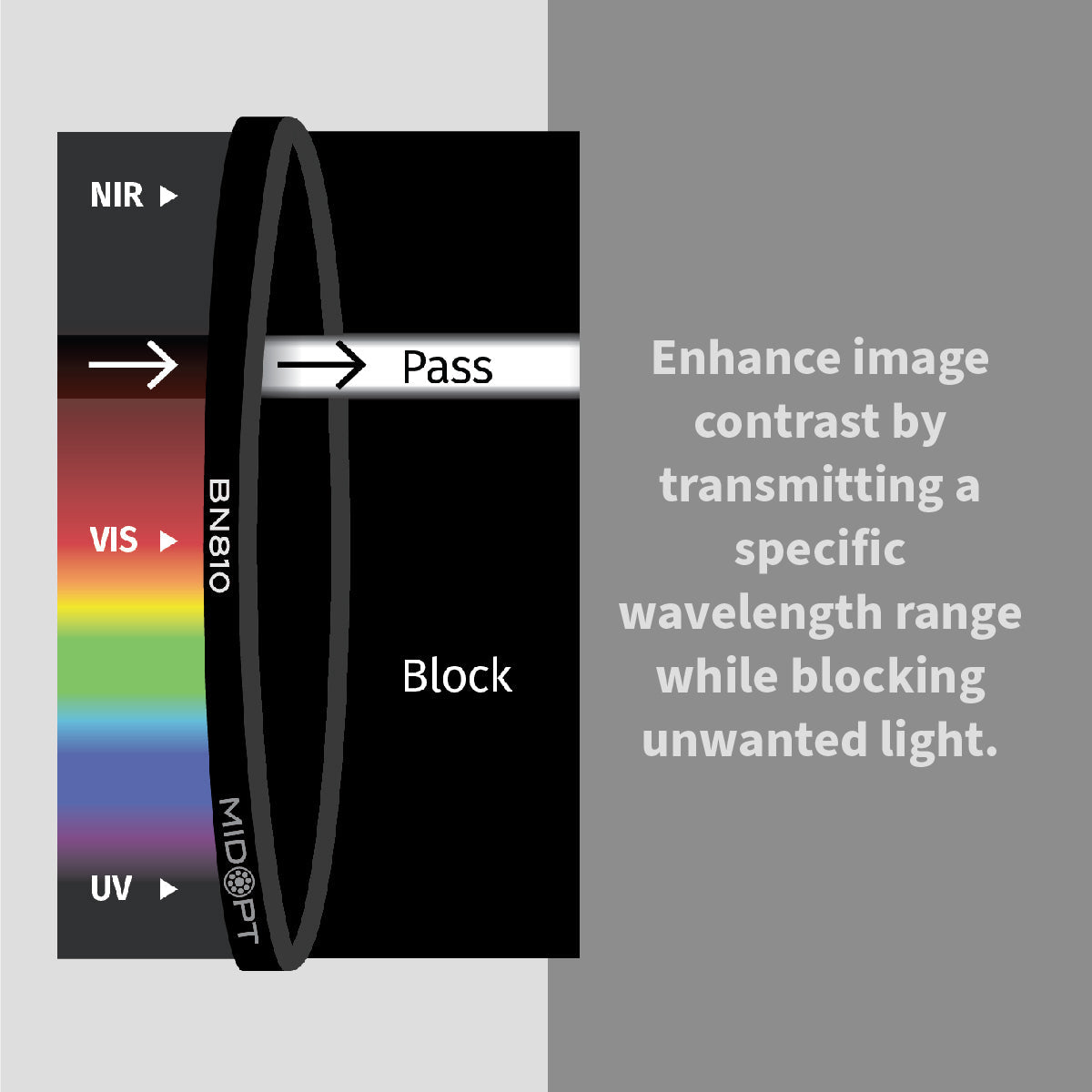

Bandpass Optical Filters

Bandpass filters allow a specific range of wavelengths to pass while blocking others. These filters are commonly used in fluorescence imaging, laser-based inspection, and applications requiring spectral precision.

Applications include:

- Fluorescence imaging

- Laser illumination systems

- Scientific and research imaging

- Automated inspection requiring wavelength isolation

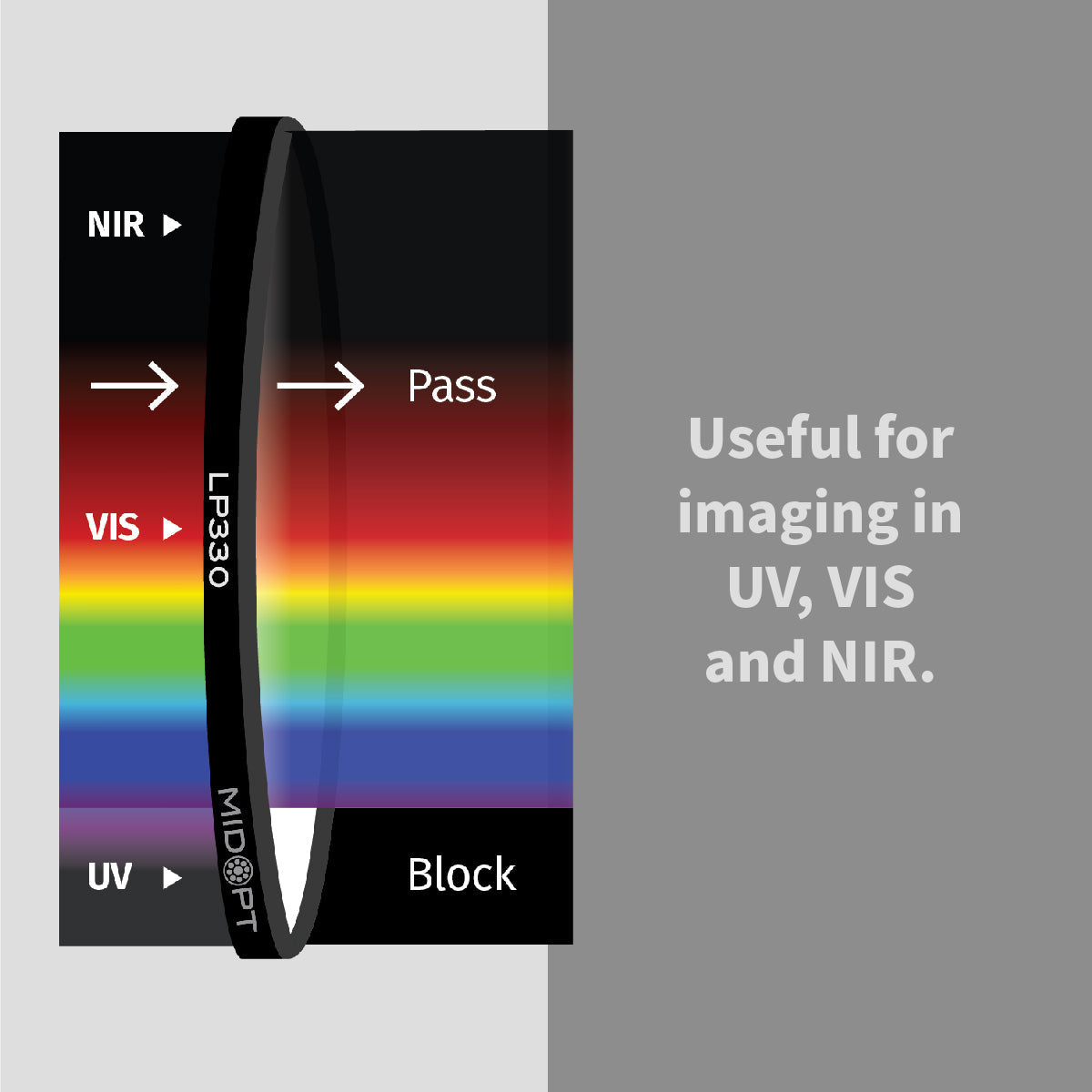

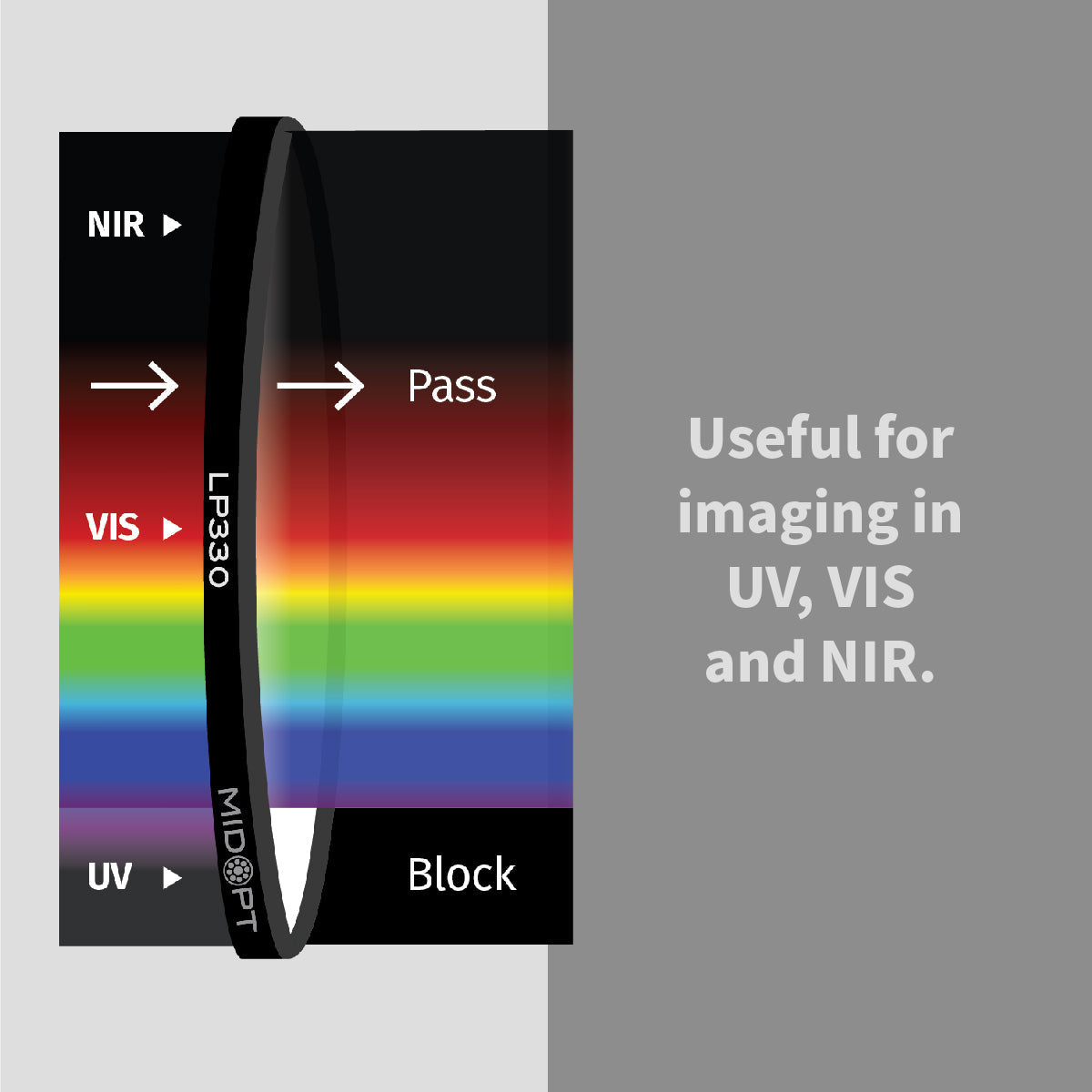

Longpass Optical Filters

Longpass filters allow longer wavelengths to pass while blocking shorter wavelengths. They are commonly used in IR imaging, fluorescence systems, and multispectral applications.

Shortpass Optical Filters

Shortpass filters transmit shorter wavelengths while blocking longer wavelengths, making them ideal for UV and visible-light filtering applications.

Neutral Density (ND) Filters

Neutral density filters reduce light intensity without affecting color balance. They are ideal for controlling exposure in bright environments or when using powerful illumination.

Explore our full range of Neutral Density Filters for precise exposure control in industrial imaging systems.

Applications include:

- High-intensity lighting setups

- Preventing sensor saturation

- Exposure control for fast-moving production lines

Polarizing Filters

Polarizing filters reduce glare and reflections caused by shiny or reflective surfaces. These filters are especially useful in quality inspection tasks involving metal, glass, or glossy materials.

Applications include:

- Surface inspection

- Packaging inspection

- Electronics and PCB analysis

- Automotive and metal part inspection

IR, UV, SWIR & LWIR Filters

Specialty filters designed for infrared and ultraviolet imaging applications support advanced scientific research, semiconductor inspection, and thermal imaging systems.

Color and Specialty Optical Filters

Color filters enhance contrast by isolating specific color channels. Specialty filters support advanced imaging needs such as UV, IR, or multispectral imaging.

Industries We Serve

Our precision optical filters are trusted across a wide range of industries where imaging accuracy and reliability are critical:

- Manufacturing & Industrial Automation

- Machine Vision & Robotics

- Semiconductor Inspection

- Life Sciences & Research Laboratories

- Aerospace & Defense Imaging

- Medical & Diagnostic Imaging

- Spectroscopy & Analytical Systems

By delivering consistent spectral performance and durability, our filters support high-precision applications in controlled and demanding environments.

Common Applications of Industrial Optical Filters

Industrial optical filters are used across a wide range of industries and imaging systems, including:

- Manufacturing & Automation: Improve inspection accuracy and defect detection

- Machine Vision Systems: Enhance contrast and reduce noise

- Robotics: Enable precise object recognition and positioning

- Electronics Inspection: Reduce glare and improve feature visibility

- Medical & Scientific Imaging: Support accurate analysis and diagnostics

- Packaging & Label Verification: Improve barcode and print readability

Filters help ensure consistent imaging performance regardless of lighting conditions or environmental challenges.

Filters in Complete Vision Systems

In industrial inspection systems, filters are selected based on lighting wavelength, lens specifications, and camera sensor response to maximize imaging precision.

How to Choose the Right Optical Filter

Choosing the correct optical filter depends on your system design and application requirements. Consider the following factors:

- Required wavelength transmission range

- Lighting source (LED, laser, halogen, ambient)

- Camera sensor sensitivity (CMOS or CCD)

- Environmental conditions (temperature, vibration)

- Filter diameter and mounting compatibility

- Required optical density and blocking level

Our team at FJW Optical can assist in identifying the optimal filter solution based on your technical specifications.

Why Buy Industrial Optical Filters from FJW Optical?

With decades of experience in industrial imaging, FJW Optical is a trusted supplier of high-performance optical components.

Why Choose FJW Optical for Precision Optical Filters

FJW Optical is a trusted supplier of high-performance optical components with decades of experience in industrial and scientific imaging.

When you choose FJW Optical, you benefit from:

- Precision-engineered wavelength control

- Consistent optical performance

- Durable construction for industrial environments

- Compatibility with leading machine vision cameras and lenses

- Custom filter manufacturing options

- Expert technical support and application guidance

We are committed to delivering reliable optical filter solutions that enhance imaging performance, reduce inspection errors, and improve system efficiency.

Industrial Optical Filters Built for Performance & Precision

Industrial optical filters are essential components for any machine vision or imaging system where accuracy and reliability matter. By controlling light, reducing interference, and enhancing image quality, these filters enable automation systems to operate with confidence and precision.

Explore our full range of industrial optical filters for machine vision, inspection, and automation to find the right solution for your application.

Recent Article : How Optical Filters Enhance Machine Vision Performance and Repeatability

Our industrial optical filters are sourced from manufacturers specializing in spectral control and contrast optimization for machine vision systems. Filters from brands like MidOpt and GOYO Optical are designed to reduce glare, isolate specific wavelengths, and enhance image accuracy across inspection, automation, and research applications.