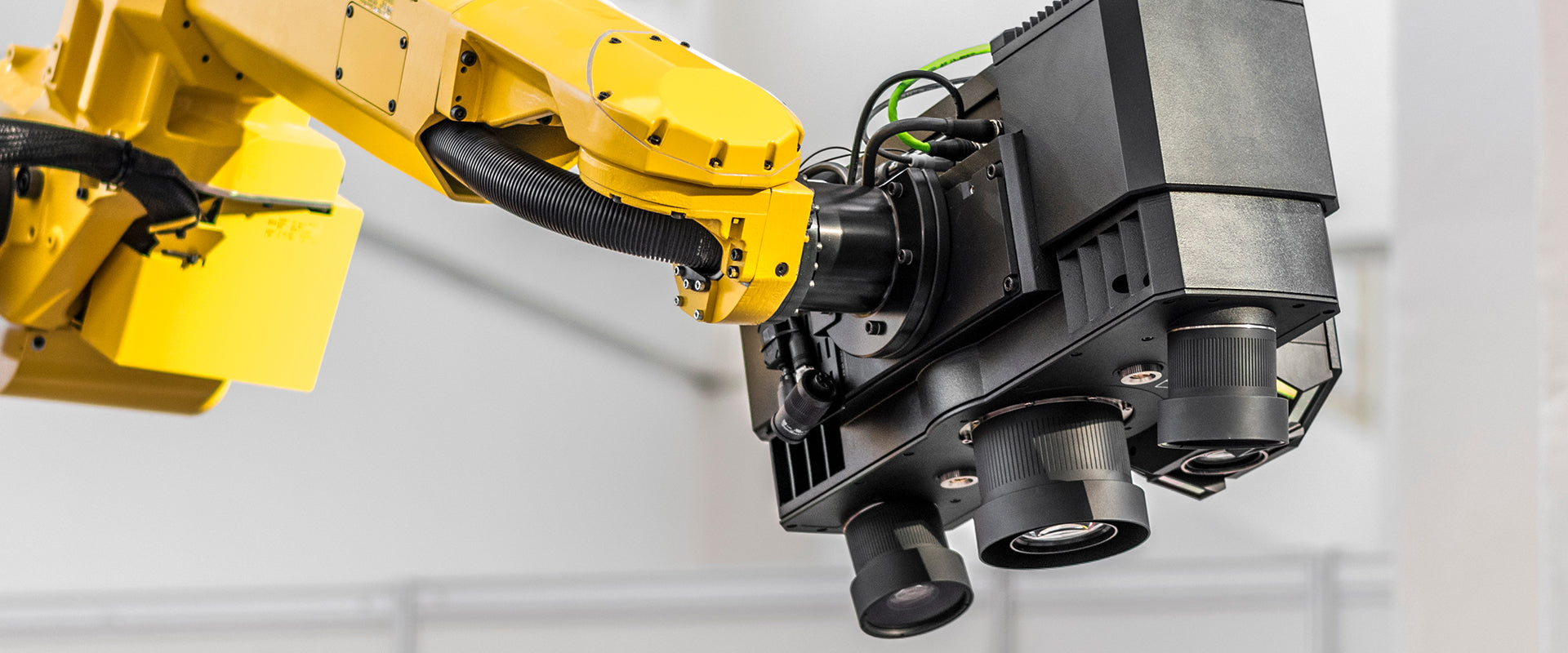

Designing a high-performance machine vision system requires more than selecting a camera and turning on a light. In industrial inspection environments, image quality determines measurement accuracy, defect detection reliability, and production efficiency.

This complete 2026 guide explains how to design a machine vision system step-by-step — from selecting industrial cameras to optimizing lighting and optical filters for maximum inspection performance.

What Is a Machine Vision System?

A machine vision system is an integrated combination of hardware and software used to automatically inspect, measure, and analyze products during manufacturing.

Unlike consumer imaging systems, industrial vision systems are designed for:

-

High-speed inspection

-

Micron-level measurement accuracy

-

24/7 reliability

-

Harsh industrial environments

A typical machine vision system includes:

-

Industrial camera

-

Precision lens

-

Controlled lighting

-

Optical filters

-

Mounting and mechanical accessories

-

Vision processing software

Each component directly impacts final image quality and inspection performance.

Core Components of a Machine Vision System

Understanding each component is critical before beginning system design.

1. Industrial Cameras

The camera is the image acquisition device and the foundation of any vision system.

When selecting industrial machine vision cameras, consider:

Resolution

Higher resolution enables detection of smaller defects but increases processing load.

Frame Rate

High-speed production lines require faster frame rates to avoid motion blur.

Sensor Type

-

CMOS sensors dominate modern industrial applications

-

Global shutter preferred for moving objects

Interface

Common interfaces include:

-

USB3 Vision

-

GigE Vision

-

CoaXPress

-

Camera Link

The right industrial camera must match your inspection speed, resolution requirements, and environmental constraints.

2. Precision Lenses

Even the best camera will fail without the correct lens.

Lenses determine:

-

Field of view

-

Magnification

-

Working distance

-

Distortion levels

Key considerations:

Sensor Compatibility

Lens image circle must match sensor size.

Focal Length

Short focal length = wider view

Long focal length = narrow field, higher magnification

Depth of Field

Critical for 3D or uneven surfaces.

Precision optical lenses must be selected based on measurement accuracy requirements — not guesswork.

3. Industrial Lighting Systems

Lighting is the most underestimated factor in machine vision system design.

Poor lighting causes:

-

Low contrast

-

Reflections

-

Washed-out images

-

False defect detection

Common lighting types:

Ring Lights

Uniform frontal illumination for flat surfaces.

Backlights

Excellent for silhouette measurement and edge detection.

Dome Lights

Diffuse lighting to eliminate glare on reflective surfaces.

Bar Lights

Directional lighting for texture enhancement.

Lighting geometry, angle, wavelength, and intensity all affect inspection results.

4. Optical Filters

Optical filters refine the light entering the camera sensor.

They are essential when:

-

Reducing glare

-

Enhancing contrast

-

Blocking ambient factory light

-

Performing infrared inspection

Common types:

Bandpass Filters

Allow only a specific wavelength to pass.

Polarizing Filters

Reduce reflections from shiny surfaces.

IR Filters

Used in near-infrared inspection systems.

Filters dramatically improve signal-to-noise ratio when properly paired with lighting.

5. Mounting & Mechanical Accessories

Stability is critical.

Vibration or misalignment can destroy measurement accuracy.

Essential accessories include:

-

Adjustable mounts

-

Extension tubes

-

Lens adapters

-

Enclosures

-

Protective housings

Proper mounting ensures consistent image alignment and repeatability.

Step-by-Step Machine Vision System Design Process

Now let’s combine all components into a structured design approach.

Step 1: Define Inspection Objective

Before choosing hardware, define:

-

What defect or feature must be detected?

-

What size tolerance is required?

-

What speed is the production line?

Without clear objectives, hardware selection becomes inefficient.

Step 2: Calculate Required Resolution

Use this formula:

Minimum Feature Size ÷ Desired Pixel Coverage = Required Pixel Resolution

Example:

If detecting a 0.1 mm defect and needing 4 pixels per feature:

0.1 mm ÷ 4 = 0.025 mm per pixel

This determines camera resolution and lens magnification.

Step 3: Select the Camera

Choose based on:

-

Resolution

-

Frame rate

-

Sensor type

-

Interface compatibility

Avoid overspending on resolution you don’t need — processing speed matters.

Step 4: Select the Lens

Match lens to:

-

Sensor format

-

Working distance

-

Field of view

-

Distortion tolerance

Test combinations when possible.

Step 5: Design the Lighting Strategy

Lighting should enhance contrast of the feature being inspected.

Examples:

-

Scratches → low-angle dark field lighting

-

Shape measurement → backlight

-

Reflective metal → dome light

Lighting is often the difference between success and failure.

Step 6: Add Optical Filters

Filters improve performance when:

-

Ambient light interferes

-

High-glare materials are present

-

Specific wavelengths enhance feature contrast

For example:

Using a red LED with a matching bandpass filter eliminates most background interference.

Step 7: Mechanical Stabilization

Secure all components using rigid mounting systems.

Ensure:

-

No vibration

-

Consistent alignment

-

Controlled working distance

Common Machine Vision Design Mistakes

Even experienced engineers make these errors:

❌ Choosing Camera First Without Defining Application

Always define inspection goals first.

❌ Ignoring Lighting Design

Lighting affects image quality more than camera specs.

❌ Using Generic Lenses

Industrial lenses are not interchangeable with consumer optics.

❌ Skipping Optical Filters

Filters significantly improve inspection reliability.

Advanced Optimization Strategies (2026)

Modern systems increasingly use:

-

High dynamic range (HDR) imaging

-

Multi-spectral illumination

-

AI-assisted defect detection

-

Coaxial lighting setups

-

Near-infrared inspection

As inspection tolerances tighten, system optimization becomes critical.

Frequently Asked Questions

How do you design a machine vision system?

Start by defining inspection requirements, then select camera, lens, lighting, filters, and mounting components based on resolution and contrast needs.

What is the most important component in a machine vision system?

Lighting is often the most critical factor because it determines contrast and defect visibility.

How do lighting and filters work together?

Lighting emits specific wavelengths. Filters isolate those wavelengths to reduce noise and improve image clarity.

Can one system handle multiple inspections?

Yes, but it requires careful optical design and possibly multiple lighting configurations.

Final Thoughts

Machine vision system design is an engineering discipline that requires precise coordination between cameras, lenses, lighting, and optical filters.

When properly designed, a machine vision system delivers:

-

Higher inspection accuracy

-

Reduced defect escape rates

-

Improved production efficiency

-

Long-term operational stability

The key is not selecting the most expensive components — but selecting the right ones.

Lighting

Lighting