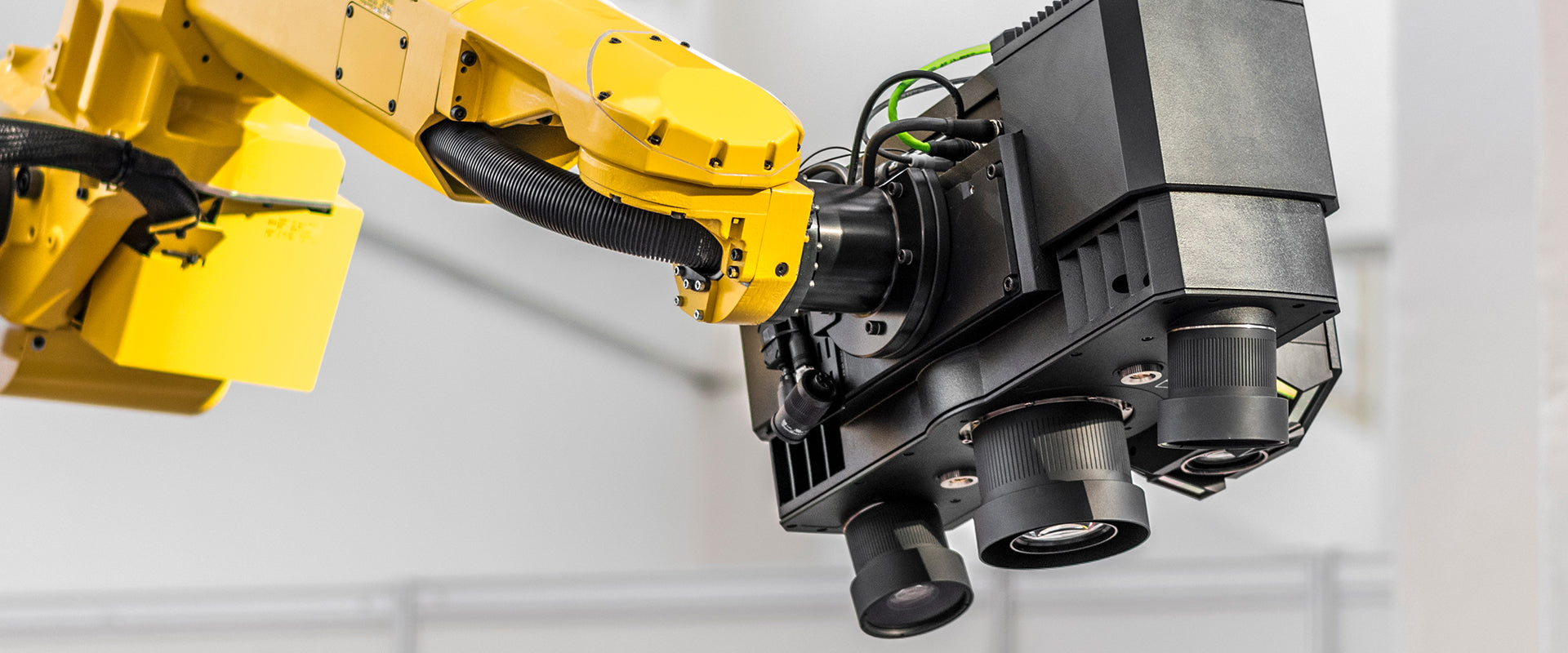

When applications are exposed to elements such as water, dirt and condensation, image quality can be significantly compromised. Grease and smudges can also negatively impact image capture results and can degrade the quality of the lens, affecting overall image clarity. These issues most commonly occur in applications that are subject to natural outdoor conditions, such as in surveillance systems and aerial imaging, or during food inspection processes.

Anti-Reflection (BBAR) Coating

MidOpt® AR (anti-reflection) Coatings reduce surface reflection to less than 1%. These coatings are optimized for the wavelength you’re trying to transmit, including UV (ultraviolet), VIS (visible) and NIR (near-infrared). Multi-layer AR Coatings are used on most MidOpt® designs.

Oleophobic Coating

MidOpt® Oleophobic Coating helps prevent fingerprint smudging, oil and other solvents from collecting on the lens in a wide range of Machine Vision applications where environmental conditions can cause imaging problems, making it ideal for Enclosure Windows.

Hydrophobic Coating

MidOpt® Hydrophobic Coatings repel water and provide excellent results in reducing fog build-up and condensation over the lens.

Some vision systems may require a custom protective window to fit the design or application requirements. Custom options include:

Silk Screening: Screen printing inks are available in a variety of colors and opacities for printing borders, masks or logos. Inks that act as optical Longpass Filters (blocking VIS light but passing NIR light) are also offered, as well as dead front printing for display and back lit applications.

Chemical Strengthening: Chemical strengthening enhances the durability and toughness of optical glass, making it six to eight times stronger than float glass. It’s an ideal solution for applications that require a high degree of resistance to breakage and shattering.

Assembly Mounting Tape: Assembly mounting tapes are available for easy assembly when screws are not an option. Very high bonding (VHB™) tape is an easier and more convenient option than cement or liquid adhesives.

Shape Molding: Protective windows can be customized to any shape or size, depending on the vision system and application requirements.

Lighting

Lighting