From Niche to Mainstream

Line scan cameras have traditionally been reserved for high-precision, high-speed applications in industries with demanding inspection requirements. But as imaging technology continues to evolve, these once-specialized tools are now being adopted across a much wider range of industries. Thanks to innovations in sensor design, interface options and form factor, line scan cameras are becoming more compact, cost-effective and easier to integrate, making them a smart choice for many mainstream applications.

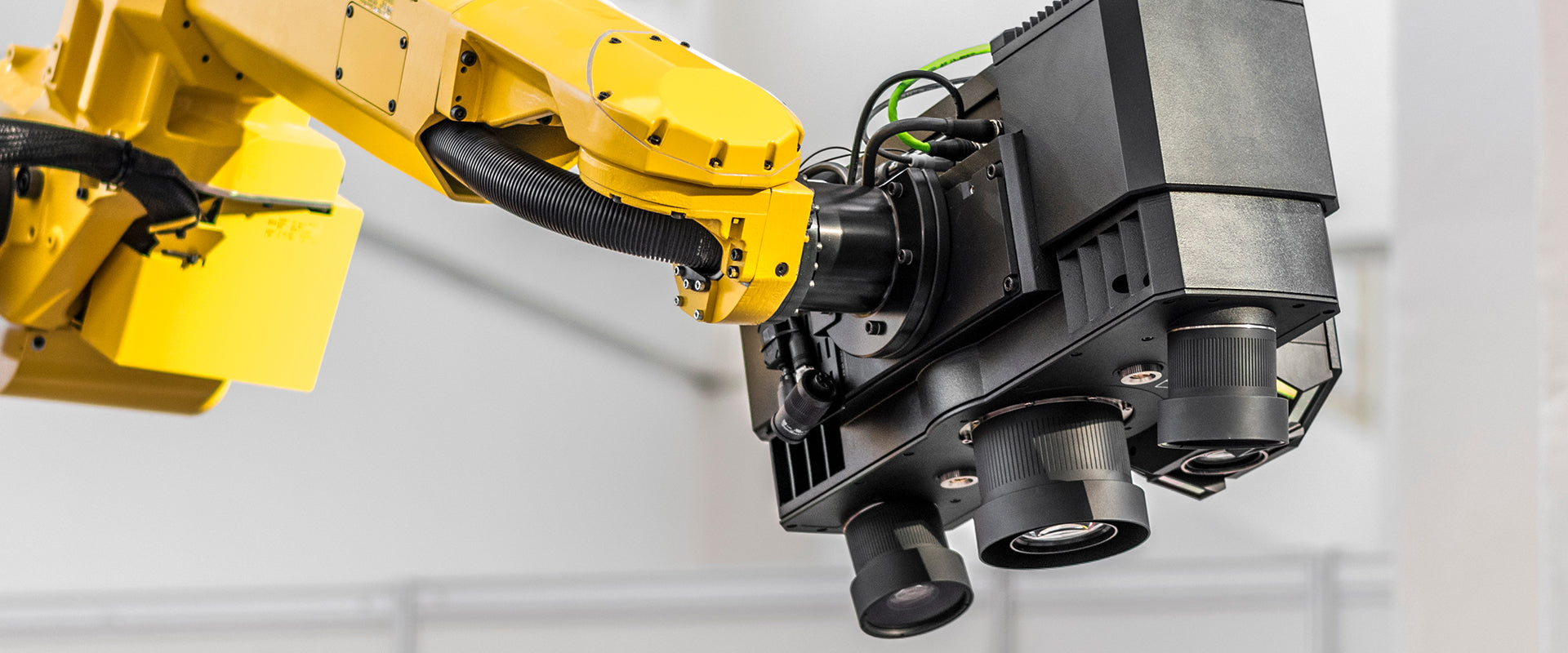

Compact Design for Modern Production Environments

One of the most notable trends in line scan camera development is the shift toward more compact designs. Today’s production environments are often tight on space and demand greater system flexibility. The latest generation of line scan cameras meets these needs with smaller form factors that are easier to install and integrate. Not only does this support more dynamic setups, but it also contributes to reduced system costs. Smaller cameras mean less material, lower production costs and easier pairing with compact lenses and lighting.

Why Line Scan Cameras Are Gaining Ground

Unlike area scan cameras, which capture full frames at once, line scan cameras capture one line of pixels at a time, making them ideal for continuous motion applications like conveyor-based inspection, web inspection and high-speed sorting. Their ability to deliver sharp, high-resolution images of moving objects is key in applications like quality control, barcode reading, surface inspection and more. As accessibility improves, line scan cameras are quickly becoming a go-to tool beyond traditional high-end use cases.

Miniaturization Through Sensor Innovation

Advancements in sensor technology are driving this wave of miniaturization. Smaller pixel sizes now allow higher resolutions within the same sensor size, while innovations like backside illumination boost light sensitivity. Modern sensors can deliver 4K resolution with pixel sizes as small as 3.5 x 3.5 microns, fitting within a compact C-mount format. New interfaces like 5GigE and CoaXPress 6 also support faster data rates, achieving up to five times the speed of traditional 1GigE connections, all at a lower system cost.

Lower Costs, Wider Adoption

As sensors become more efficient to manufacture, overall costs are falling. Producing more sensors per silicon wafer reduces per-unit costs, and the use of smaller-diameter lenses further helps reduce system expense without sacrificing optical performance. Combined with the growing availability of C-mount lenses and more efficient LED lighting, line scan vision systems are now more affordable than ever, opening doors for use in applications ranging from electronics inspection to agricultural sorting.

Lighting

Lighting