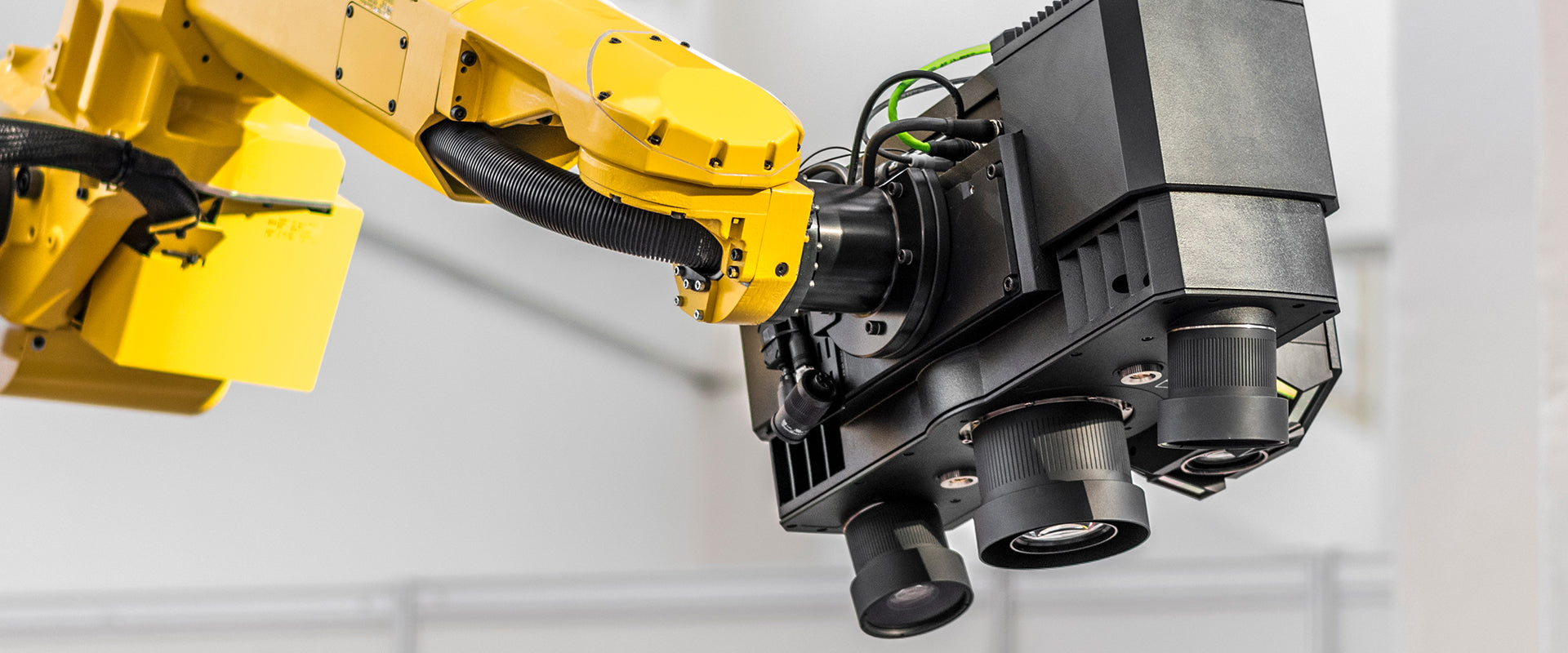

Quality standards continue to rise in manufacturing environments while defect tolerance grows increasingly narrow. Traditional machine vision systems, typically relying on standard color or monochrome sensors, can struggle to catch flaws that are invisible to the human eye or obscured by lighting, surface finishes or material properties. Because of this, multispectral imaging has become a powerful tool for advanced inspection.

What Is Multispectral Imaging?

Multispectral imaging captures image data at multiple, distinct wavelength bands rather than relying solely on the visible RGB spectrum. These bands may include:

- Visible light (RGB)

- Near-infrared (NIR)

- Short-wave infrared (SWIR)

- Ultraviolet (UV)

- Specialized narrow wavelength ranges

By analyzing how materials absorb, reflect or transmit light at different wavelengths, multispectral cameras reveal features and defects that standard cameras cannot.

Why Conventional Imaging Misses Critical Defects

Typical color cameras operate using broadband RGB filters that approximate human vision. While effective for general inspection, this approach is limited:

- Certain coatings or contaminants may appear identical in RGB.

- Surface reflections can mask defects under visible light.

- Internal structures beneath plastics, films or coatings cannot be seen.

- Moisture, adhesives and chemical differences don't always produce visible contrast.

Multispectral systems are designed to overcome these limitations by uncovering properties that differ across wavelengths.

How Multispectral Imaging Reveals Hidden Defects

1. Detecting Foreign Contaminants: Different materials reflect light uniquely across the spectrum. In NIR, for example: Dust, fibers, oils or adhesives may become highly visible; and organic materials often appear with stronger contrast. This allows contaminants to be detected even when they blend with the product in visible light.

2. Revealing Subsurface Defects: Infrared wavelengths penetrate deeper into materials than visible light. This makes it possible to detect: cracks beneath coatings, delamination in composites, bubbles in plastics and hidden voids in castings or molded components. SWIR (short-wave infrared) imaging in particular excels at exposing features beneath certain polymers and films.

3. Identifying Variations in Coatings and Finishes: Multispectral imaging can differentiate: coating thickness, application uniformity, chemical composition changes and areas where coatings have been improperly cured. Even if the outer surface looks identical in RGB, the differences are unmistakable in specific spectral bands.

4. Moisture & Chemical Detection: Many materials absorb IR wavelengths differently when moisture or certain chemicals are present. This enables: Leak detection, seal integrity checks, moisture content measurement and verification of cleaning processes. These types of inspections are nearly impossible with standard imaging.

5. Sorting and Inspection by Material Type: Distinct materials, like metals, plastics, textiles and food products, exhibit unique spectral responses. This makes multispectral imaging valuable for: automated sorting, recycling systems, agricultural quality grading and pharmaceutical inspection.

Single-Sensor vs. Multi-Sensor Multispectral Cameras

Modern multispectral cameras come in multiple configurations to meet different application needs:

Single-Sensor Cameras with On-Sensor Filters

- Compact and cost-effective

- Capture multiple spectral bands in one exposure

- Ideal for high-speed inspections

Prism-Based Multi-Sensor Cameras

- Separate sensors for each spectral channel

- Superior alignment, precision and color separation

- Best for demanding inspection tasks requiring exact spectral fidelity

Each approach offers advantages depending on resolution, speed and wavelength requirements.

Real-World Applications of Multispectral Inspection

- Electronics: Detecting contamination, solder defects, underfill issues

- Pharmaceuticals: Tablet inspection, blister pack integrity, coating consistency

- Food & Agriculture: Sorting produce by ripeness, bruising or contamination

- Textiles: Weave defects, dye variation, fiber composition

- Automotive: Adhesive bead verification, composites inspection

- Medical Devices: Ensuring cleanliness, sealing, bonding and material integrity

Across industries, multispectral systems help reduce scrap, improve yield and catch subtle issues before they reach the customer.

As sensors become faster, sensitivity improves and new wavelengths are integrated, multispectral imaging continues to expand into areas once considered too complex for machine vision. With the growing demand for automation and zero-defect manufacturing, multispectral inspection is transitioning from a niche capability to a mainstream requirement.

Lighting

Lighting