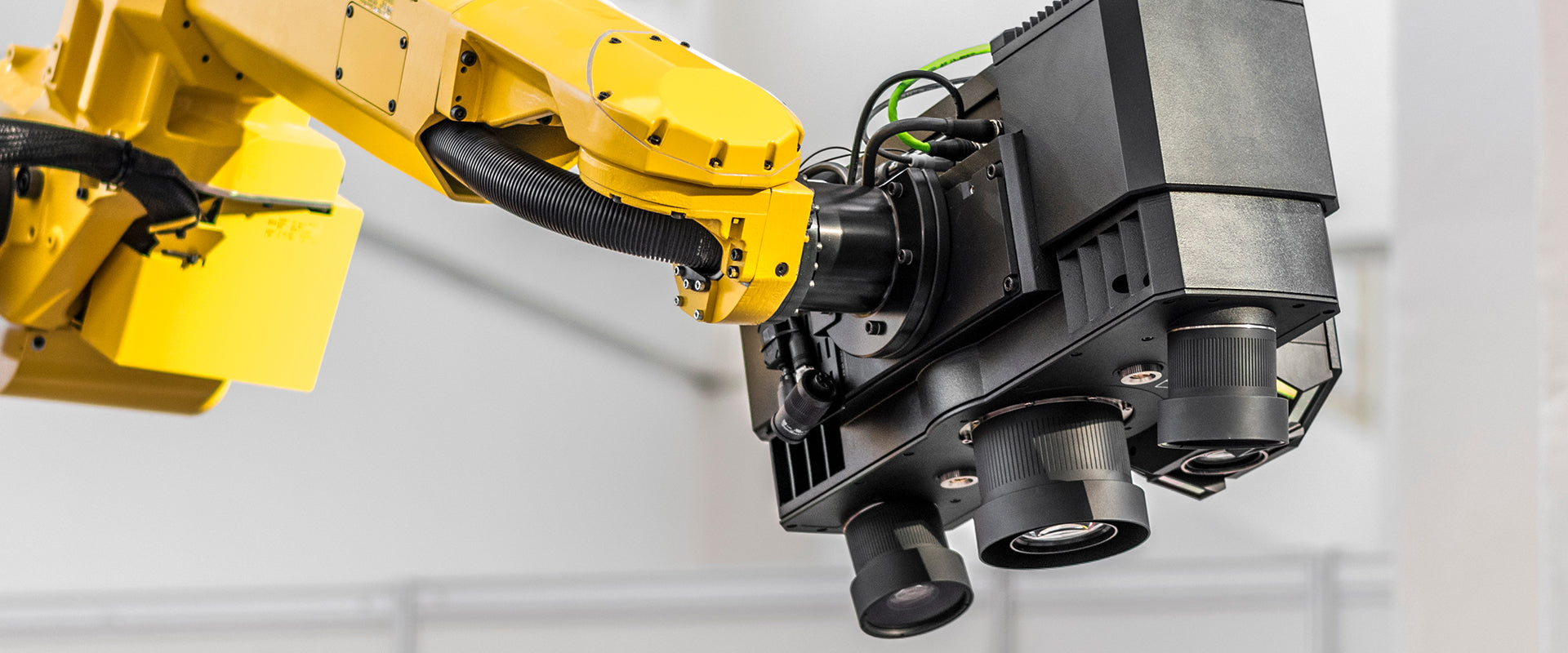

Choosing the right lens for a machine vision system involves more than focal length, resolution and working distance. The lens mount, the mechanical interface between the camera and lens, is one of the most important factors in ensuring proper imaging performance. The mount not only affects compatibility, but also impacts back focal distance, sensor coverage, optical stability and the overall footprint of the system.

Understanding the differences between popular machine vision mounts such as C-mount, CS-mount, and M12 (S-mount) helps ensure that lenses and cameras work seamlessly together, especially as sensors evolve toward higher resolutions and smaller pixel sizes.

C-Mount Lenses

C-mounts are the most common standard in machine vision. They feature a 1-inch diameter threaded mount with a 32TPI (threads per inch) pitch and a 17.526mm flange focal distance.

Advantages

- Highly versatile – supports a wide range of focal lengths, from wide-angle to telephoto

- Compatible with many sensor sizes, typically up to 1.1"

- Secure mechanical connection ideal for industrial environments

- Large selection of lenses, including high-resolution, low-distortion and ruggedized options

Best For: factory automation, electronics inspection, robotics, measurement systems and applications requiring interchangeable lenses with stable alignment.

CS-Mount Lenses

CS-mounts use the same thread as C-mounts but with a shorter flange focal distance: 12.526mm – exactly 5mm shorter than C-mounts.

Advantages

- Compact – CS lenses are often smaller and lighter

- Lower cost – ideal for cost-sensitive vision projects

- Optimized for small-format sensors, typically 1/2" or smaller

A C-mount lens can be used on a CS-mount camera with a 5mm adapter, but CS lenses cannot be used on C-mount cameras due to insufficient back focal distance.

Best For: embedded vision, security imaging, compact inspection systems and applications where space is limited.

M12 (S-Mount) Lenses

M12 or “S-mount” lenses use a 12mm diameter thread and don't include a standardized flange focal distance. Instead, the lens is positioned by screwing it in or out until focus is achieved.

Advantages

- Extremely compact – ideal for small sensors and embedded boards

- Lightweight and cost-effective

- Available in a wide range of focal lengths, including ultra-wide options

- Popular for mobile, automotive and lightweight robotic systems

Limitations

- Lower precision compared to C / CS mounts

- More susceptible to vibration unless secured with adhesive or set screws

- Typically limited sensor coverage (1/2" or smaller)

Best For: IoT devices, small embedded cameras, UAV systems, in-vehicle cameras, compact consumer and industrial imaging.

Other Specialized Lens Mounts

While C, CS, and M12 are the most common in machine vision, several additional mounts serve specialized applications:

M-Mount (M42, M58, MFT, etc.)

Larger industrial cameras often use metric-thread mounts such as M42, M58, or MFT. These mounts support: large-format sensors, telecentric lenses and high-resolution optics for metrology. They're best for applications demanding extreme precision, such as semiconductor inspection or 3D metrology.

F-Mount (Nikon-Style)

Originally designed for DSLRs, F-mount lenses are used in machine vision systems requiring: large sensor formats, long working distances, or high optical quality. F-mounts are common in scientific imaging and high-end industrial inspection.

TFL and TFL-II Mounts

As sensors move toward smaller pixel sizes (e.g., 2 µm or below) and larger formats (1.1" and beyond), TFL/TFL-II mounts are gaining popularity. TFL: M35 × 0.75 thread; TFL-II: M35 × 0.75 thread with different mechanical specifications; Flange focal distance: 17.526mm (matching C-mount). These mounts provide greater mechanical stability for high-resolution lenses where precise optical alignment is critical.

When selecting the right lens mount for your application, consider sensor size compatibility, required optical precision, system footprint, environmental conditions and budget and scalability.

Lighting

Lighting