In machine vision, lighting is important. The quality, angle and consistency of illumination directly impact the ability of your vision system to capture accurate, reliable images. Among the many lighting considerations, one crucial yet often overlooked factor is uniformity – achieving even, consistent illumination across the entire field of view.

What Is Uniformity in Machine Vision Lighting?

Uniformity refers to how evenly light is distributed over the target surface or scene. Ideally, every part of the object under inspection should be illuminated with the same intensity to avoid bright spots, shadows or gradients that can confuse your vision algorithms or degrade image quality.

Inconsistent lighting can cause problems such as:

- False defect detection from shadows or glare

- Poor contrast between features and background

- Reduced accuracy in color or shape analysis

- Increased calibration time and system downtime

Why Uniform Lighting Matters

Even illumination is essential to:

- Enhance Image Quality: Uniform lighting reduces harsh shadows and hotspots, providing a clear, consistent image that enables better edge detection, measurement accuracy and pattern recognition.

- Improve Inspection Reliability: When every pixel sees the same amount of light, machine vision algorithms can more reliably differentiate between genuine defects and lighting artifacts.

- Simplify System Setup and Maintenance: Consistent illumination reduces the need for frequent recalibration or adjustment, saving time and cost over the life of the vision system.

How to Achieve Uniform Lighting

Achieving uniformity involves careful selection and positioning of your lighting components. Here are some key approaches used in the industry:

Diffuse Lighting

Using diffusers or integrating spheres scatters light evenly to minimize shadows and hotspots, ideal for highly reflective or textured surfaces.

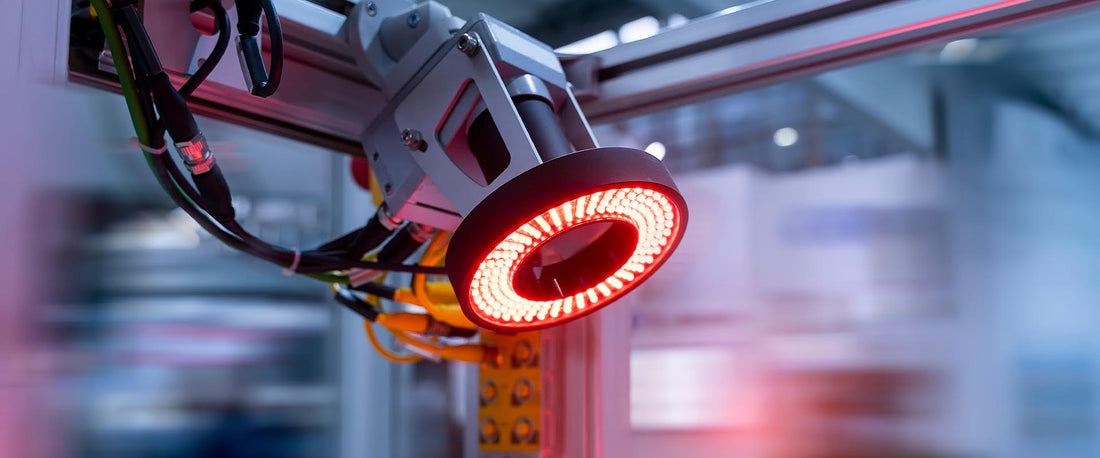

Ring Lights and Dome Lights

These light sources surround the lens or target area to provide 360-degree illumination, ensuring even light distribution and reducing specular reflections.

Backlighting

By placing the light source behind the object, backlighting highlights edges and shapes with stark contrast, useful for silhouette inspection.

High-Quality LED Arrays

LED arrays with precise spacing and adjustable intensity offer tunable uniform illumination, allowing for custom solutions tailored to specific applications.

Uniform lighting is a critical component that can make or break the success of your machine vision application. By investing in high-quality, uniform illumination, we can enhance image quality, reduce inspection errors and improve overall system reliability.

Lighting

Lighting