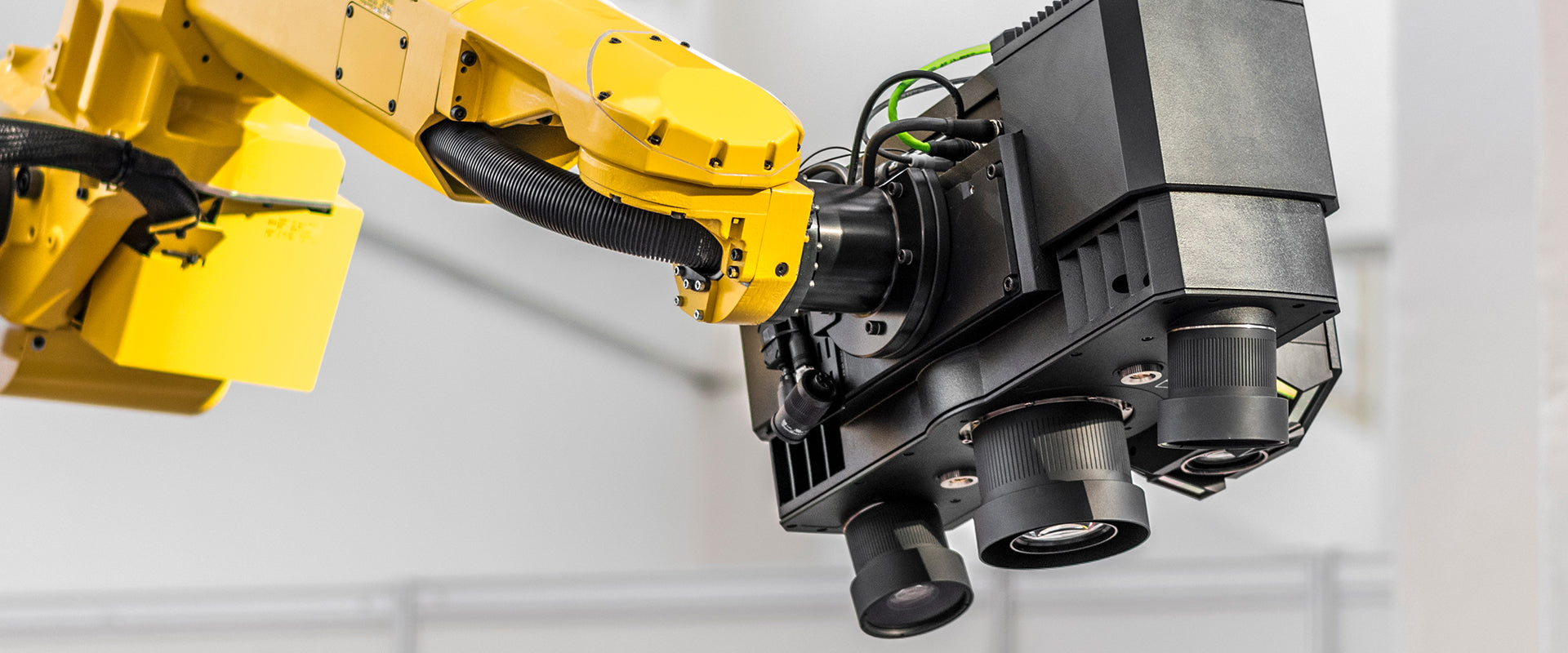

Lighting is one of the most influential factors in machine vision performance. The right illumination can dramatically improve contrast, reduce noise and stabilize inspection results, while the wrong setup can cause missed defects, blurry images or inconsistent measurements.

Two of the most common lighting approaches are continuous lighting and strobe (pulsed) lighting. Both are widely used in machine vision, but each is suited to different types of applications. Understanding the differences will help you select the best method for accuracy, speed, reliability and system longevity.

What Is Continuous Lighting?

Continuous lighting provides a steady, uninterrupted light output while the vision system is running. LED ring lights, bar lights, backlights and area lights are frequently used in this mode.

Advantages of Continuous Lighting

✔ Ideal for static or slow-moving targets: objects that remain still or move slowly can be captured clearly without additional light timing.

✔ Easier setup and integration: no need to synchronize lighting with the camera’s exposure.

✔ Stable illumination for human inspection: operators can see the illuminated area at all times, which helps during manual alignment or setup.

✔ Lower electrical stress on LEDs: with proper thermal management, continuous lighting can prolong LED lifespan.

Best For: dimensional inspection of stationary parts, manual inspection stations, vision systems with longer exposure times, applications that don’t require motion freeze.

What Is Strobe (Pulsed) Lighting?

Strobe lighting delivers extremely short, high-intensity bursts of light, often much brighter than continuous illumination, synchronized to the camera's exposure window.

Advantages of Strobe Lighting

✔ Freezes fast motion: a microsecond-range pulse can "stop" high-speed objects, eliminating blur in conveyor or robotic applications.

✔ Higher brightness without overheating: because light is delivered in very short bursts, LEDs can safely operate at much higher output levels than in continuous mode.

✔ Improved contrast and image sharpness: pulsing can overcome ambient light interference and produce stronger, cleaner edges and features.

✔ Energy-efficient for high-speed systems: lights are only on during the exposure period, reducing overall power consumption.

Best For: high-speed production lines, capturing fast-moving objects or rotating components, reducing motion blur, situations requiring very short exposure times and environments with strong ambient light.

Comparing Strobing vs. Continuous Lighting

| Factor | Continuous Lighting | Strobe Lighting |

|---|---|---|

| Motion control | Good for slow/static | Excellent for fast-moving |

| Brightness | Limited by heat | Very high (short pulses) |

| Power use | Constant | Low overall, short bursts |

| LED lifespan | Stable when cooled | Reduced if overdriven excessively |

| Setup complexity | Simple | Requires timing/sync |

| Cost | Generally lower | May need controllers |

When Strobe Lighting Is the Better Choice

Consider strobing if your application includes:

- Fast-moving conveyors

- High-speed printing or labeling inspection

- Bottle, can, or packaging lines

- Automotive components in motion

- Rotating shafts, gears, or rollers

- High ambient light that washes out images

Strobing enables very short exposures while maintaining brightness, helping ensure crisp, blur-free imaging even at high production velocities.

When to Use Continuous Lighting

Choose continuous lighting if your system involves:

- Static or slow-moving parts

- Manual operator alignment

- Long exposure times

- Applications sensitive to electrical noise

- Situations where simple integration is preferred

Continuous lighting is also ideal for systems requiring constant visual feedback.

Hybrid Approaches: The Best of Both

Many modern machine vision systems use hybrid illumination, such as:

- Continuous background lighting with strobed front lighting

- Constant low-level illumination with a high-intensity pulse during capture

- Synchronized multi-light strobing to create different contrast conditions

This approach can enhance surface inspection, highlight defects from multiple angles and increase throughput.

There isn't a universal best lighting mode – only the best choice for your application. If your system requires motion freeze, extreme contrast or short exposure times, strobe lighting may be the best option. If you have a simpler setup, manual inspection or slow / static objects, continuous lighting provides stability and ease of use.

Lighting

Lighting