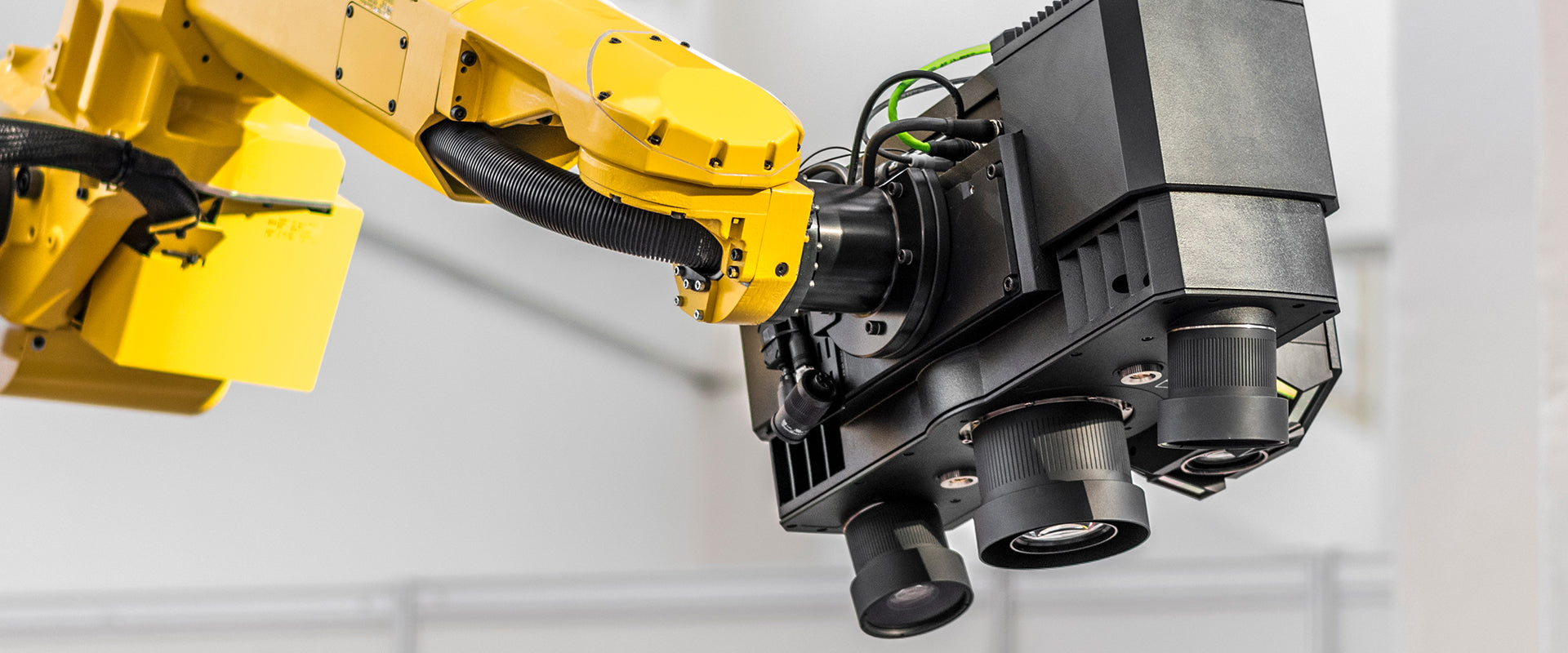

Achieving accurate, repeatable results depends on far more than just selecting the right camera or lens. One of the most overlooked components in many imaging systems is the optical filter. When properly selected, filters dramatically improve image quality, reduce variability and ensure consistent performance across changing environments.

Why Optical Filters Matter in Machine Vision

Machine vision systems rely on precise light control. Without filtering, cameras capture unwanted wavelengths, ambient light, glare and reflections that introduce noise and reduce contrast. These inconsistencies can lead to:

- False positives or missed defects

- Reduced measurement accuracy

- Inconsistent results between shifts or facilities

- Increased post-processing and tuning

Improving Image Contrast and Clarity

High contrast is essential for accurate detection, measurement and inspection. Filters enhance contrast by:

- Blocking ambient or stray light

- Isolating specific LED wavelengths

- Reducing reflections from shiny surfaces

- Improving edge definition and feature separation

Repeatability is critical in automated inspection systems. Filters help maintain consistent imaging performance by reducing sensitivity to:

- Changes in ambient lighting

- Variations in part surface finish

- LED intensity fluctuations

- Camera angle or lens field of view

Most machine vision systems use LEDs with a bell-shaped spectral output. Filters designed to match this profile capture more usable light while blocking unwanted wavelengths, resulting in:

- Higher signal-to-noise ratio

- Improved exposure control

- Reduced image noise

- Faster inspection speeds

In high-intensity or broadband lighting conditions, neutral density (ND) filters help regulate exposure without altering color balance. ND filters are especially useful when:

- Sensors are oversaturating

- Longer exposure times are needed

- Depth of field must be controlled

- Illumination cannot be reduced

Filters also serve as protective elements, shielding cameras from dust, debris, moisture and harsh environments. Protective windows and coated filters preserve image quality while extending equipment life, important in industrial and outdoor installations. Durable coatings such as anti-reflection (AR), oleophobic and scratch-resistant layers reduce maintenance while maintaining optical clarity.

The optimal filter depends on several factors:

- Lighting wavelength

- Camera sensor type

- Lens field of view

- Environment (indoor, outdoor, high temperature, moisture)

- Inspection goals (contrast, measurement, detection)

Lighting

Lighting